BME100 s2017:Group6 W1030AM L2

| Home People Lab Write-Up 1 | Lab Write-Up 2 | Lab Write-Up 3 Lab Write-Up 4 | Lab Write-Up 5 | Lab Write-Up 6 Course Logistics For Instructors Photos Wiki Editing Help | |||||||

OUR TEAM

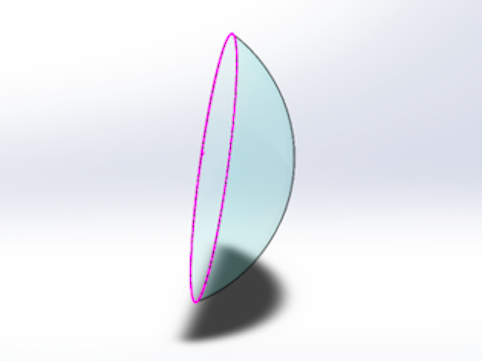

LAB 2 WRITE-UPDevice Image and DescriptionOur prototype is a silicone-hydrogel contact lens. These contact lenses contain a color changing indicator (dye) located on the rims of the contact lens. These indicators are a timed- oxidation reaction designed to fully react in one month’s time. By indicating when it is time to replace the contacts, the indicator serves as a helpful reminder for the user to remove and change their contact lens. This prevents the user from overusing their contacts and developing eye infections or eye damage.

Technical and Clinical FeasibilityTechnical Feasibility The indicator is a type of dye that changes color based on Oxygen exposure, as other choices were too risky to be in close contact with the surface of the eye. This is the only place where this device could fail and potentially cause permanent damage. We give our product a 2 for technical feasibility. There are many methods and materials that could be used to change color over time, but finding one that changes over the correct period of time may be difficult. Additionally, we have yet to address in detail the process of injecting or inserting dye into the contact lens.

We also gave our product a 2 for clinical feasibility. Research on certain dyes and indicators are necessary, in order to determine the safety of these substances when inserted into the eye. Additionally, the dyes may prove inaccurate when changing in the correct time period, which could make the lenses less reliable in predicting replacement time.

Market AnalysisValue Creation Manufacturing Cost Sales Price Market Size About 13.2 million people use monthly contacts in the U.S. per year. The average cost of monthly contacts is around $12.00 per pair. Therefore, the market size is approximately $1.6 billion. On the fundability worksheet, the market size has a score of 3.

Fundability DiscussionAccording to the fundability worksheet, our project should be funded. The majority of our scores are 2 or 3, and the score of 3 in market size is a promising aspect of our design. The only component of our Fundability Worksheet that received a score below 2 was the Customer Validation section with a score of 1. This is due to the fact that our product has not been widely advertised and is new to the consumer market. Additionally, this is a technically simple device with relatively high chance of clinical success, which gives clinical and technical feasibility scores of 2.

|

|||||||