Free Air Space Testing Procedure

Back to Protocols

Introduction

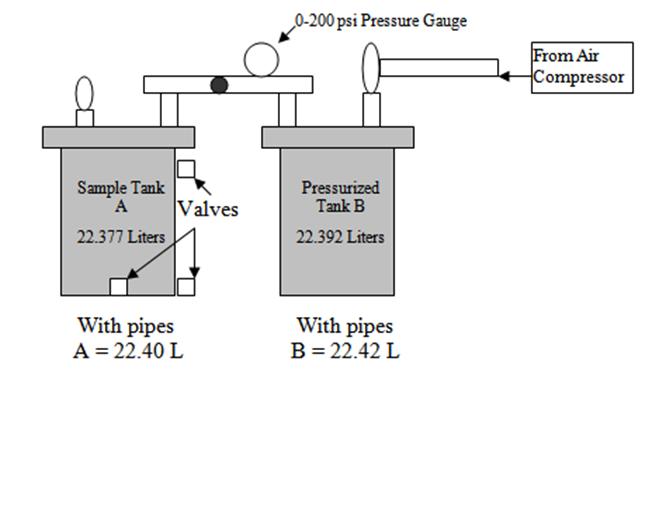

Most methods of determining Free Air Space (FAS) use a pycnometer. Pycnometers are simple devices that work according to Boyle's Law PV=nRT. A sample is placed in an airtight chamber (Sample Tank A) with a known volume. Then a known volume of gas at a known pressure (from Pressurized Tank B) is released into the sample chamber to equalize the pressure between the two tanks. Based on the change in pressure, the air-filled void space of the sample can be calculated.

Two iron tanks were custom-made with 12 bolts so the lid could be tightened down onto an O-ring to provide an airtight seal. The interior of the tanks is nominally 12 inches (30.5 cm) high and 12 inches (30.5 cm) in diameter. The tanks were pressure tested safely at 40 psi (abs).

Materials Needed

Pycnometer

sample

stilts

scale

plenums

a regulated 30-psi compressed air source

Pycnometer Directions

- Place four 1-inch PVC spacers and one of the plenums in the bottom of the pycnometer.

- Weight and tare the pycnometer with the plenum and add the sample until the desired weight and/or height is reached.

- Level the sample in the pycnometer and place a plenum and four spacers on top of the plenum. Place stilts of proper length in each one of the spacers so that the sample is under a minor amount of compression when the lid is tightened. The volume of the sample can be easily calculated from the lookup chart below. Record the length of the stilts placed in the pycnometer.

- Tighten the twelve bolts on top of the pycnometer. They do not have to be overly tight since the O-ring provides a good seal.

- Connect Tank A to Tank B and open the valve between the two tanks and at least one of the valves connected to Tank A.

- Record the background pressure gauge reading and make sure all the valves are shut.

- Pressurize Tank B to around 30 psi (2.069E+05 Pa). Close the valve attached to the compressed air line and listen and feel for leaks. Record the pressure reading after the gauge has stabilized (starting pressure); if the gauge doesn't stabilize the tank is probably leaking.

- Open the ball valve between the two tanks and listen and feel for leaks.

- Record the highest reading the pressure gauge gives (final pressure).

- Slowly release the pressure by opening the valve on the lid of Tank A.

- After a few minutes all the air pressure should be released and repeat the test by returning to step 5. It is recommended to have triplicate tests of each sample. If the test is completed continue to step 12.

- Remove Tank A's lid and either remove the sample and test a different sample or add different size stilts and use the same steps for a denser sample.

- Note: The spacers and plenums are optional if you are not comparing different densities of a sample. However, the spacers and plenums are a good way of calculating the volume of the sample.

Calculations

FAS of a sample can be calculated by:

Where:

- Pi = absolute starting pressure (starting pressure - background pressure)

- Pf = final absolute pressure, corrected for gauge drift and background pressure, presently:

- Pf (corrected) = 1.0028 * (final pressure - background pressure) + 0.1579, all in psi

- VB = Volume of Tank B with pipes

- VA = Volume of Tank A with pipes

- VS = Sample Volume

- VT = Volume occupied by plastic (spacers, stilts and plenums)