Droplet Microfluidics: Emulsion Droplets - Wenyun Wang

Introduction

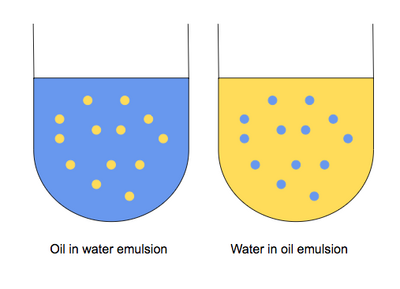

An emulsion is defined as a phenomenon in which two immiscible fluids are mixed together and droplets of one fluid are dispersed in a second fluid, as shown in Figure 1. Emulsions are critical in many fields, such as coating processes, food manufacturing, and even personal care products. However, as precise size control of the emulsion droplets can be hard, it sets the limit in many applications. One way to solve this problem is by using capillary microfluidic devices.[1]

Capillary Microfluidic Devices

Co-flow Microfluidic Devices

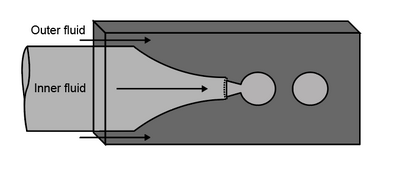

As shown in Figure 2a, the capillary microfluidic device consists of two concentric glass capillaries. There is a circular glass capillary and a square capillary. The fabrication procedure starts with preparing an initial circular glass capillary with an outer diameter size of 1-2 mm, which is then heated and pulled to form a tapered geometry that has a fine orifice at the end. The circular glass capillary is for the inner fluid to travel through and the square capillary is for the outer fluid. By combining this circular capillary with a square glass capillary which has the same inner diameter as the circular one, the microfluidic device is formed with a geometry known as co-flow geometry. When the inner fluid and the outer fluid is flowing the same direction through the coaxially aligned capillaries, a coaxial flow of the fluids is generated.[1]

Flow-focusing Microfluidic Devices

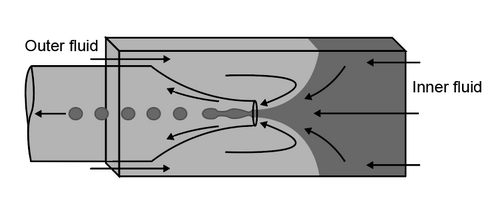

An alternative design of the microfluidic device to form single emulsion droplet is shown in Figure 3, which is known as flow-focusing geometry. It differs from the co-flow geometry as the two fluids are introduced at the opposite ends of the same square capillary. With this flow-focusing geometry, the monodisperse droplets are able to achieve a size of about 1-5 μm in diameter, which is smaller than the size of the orifice.[1]

Droplets can also be formed using T-junction: https://openwetware.org/wiki/Droplet_Microfluidics:_T-Junction_-_Lina_Wu

Dripping and Jetting

In order to understand the formation of droplets resulted from breakup of a coaxial flow, two mechanisms are defined, which are dripping and jetting. If dripping is taking place, the emulsion droplets form shortly after leaving the capillary tubes with the same diameter as the capillary orifice as shown in Figure 2b. This process happens at lower flow rates and typically produces highly monodisperse droplets. Alternatively, at higher flow rates, jetting would occur instead. In this process, the flow would breakup into droplets at about three or more orifice diameters after leaving the capillaries. Jetting usually produces polydisperse droplets with greater radii than the jet as shown in Figure 2c. Jetting can be caused when the large viscous stress of the outer fluid has a much larger viscosity than that of the inner fluid. Because in this case, viscous effects would dominate over inertial effect and lead to a low Reynolds number as a result.[2][4]

More about dripping and jetting can be found: https://openwetware.org/wiki/Droplet_Microfluidics:_T-Junction_-_Lina_Wu

More about Reyolds number can be found: https://openwetware.org/wiki/Reynolds_Number_(Re)_-_Blayne_Sarazin

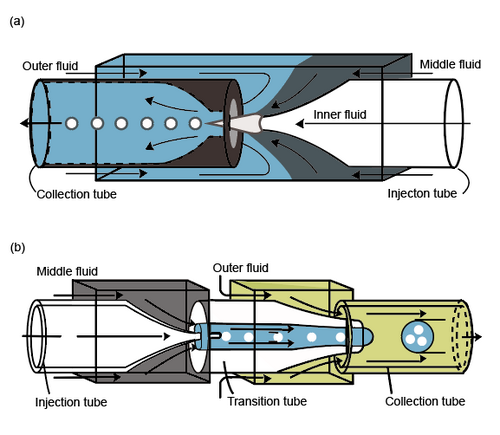

Multiple Emulsions

Multiple Emulsion refers to the system where multiple hierarchical of smaller droplets are contained inside the dispersed droplets. For example, an illustration of double emulsions is shown in Figure 4c and 4d. Typically, multiple emulsion generators are combined sequentially to produce emulsions of higher orders. To form double emulsions, two co-flow emulsion generators can be used as shown in Figure 4b. An alternative approach, which is shown in Figure 4a, can also serve the same purpose. It combines co-flow geometry and flow-focus geometry so that double emulsions can be achieved within one step.[1][2][5]

Applications

Applications of controlled emulsions cover a wide range of varieties, such as fabrication of Janus particles, porous materials, vesicles, lipid crystal cells, pharmaceutical usages, and extraction processing, etc.[1][6]

More about the application in synthesizing Janus particles can be found: https://openwetware.org/wiki/Droplet_Microfluidics:_Synthesis_of_Janus_Particles-_Teresa_Wang

References

1. Shah, R. K.; Shum, H. C.; Rowat, A. C.; Lee, D.; Agresti, J. J.; Utada, A. S.; Chu, L.-Y.; Kim, J.-W.; Fernandez-Nieves, A.; Martinez, C. J.; Weitz, D. A. "Monodisperse Double Emulsions Generated from a Microcapillary Device." Materials Today 2008, 11 (4), 18–27. DOI:https://doi.org/10.1016/S1369-7021(08)70053-1

2. Utada, A. S.; Lorenceau, E.; Link, D. R.; Kaplan, P. D.; Stone, H. A.; Weitz, D. A. "Monodisperse Double Emulsions Generated from a Microcapillary Device." Science 2005, 308 (5721), 537–541. DOI:https://doi.org/10.1126/science.1109164

3. Emulsion: Mechanism, Types, Uses, Emulsifying Agents, Videos, Example. https://www.toppr.com/guides/chemistry/surface-chemistry/emulsions/ (accessed Feb 25, 2019).

4. Kim, S.-H.; Weitz, D. A. "One-Step Emulsification of Multiple Concentric Shells with Capillary Microfluidic Devices." Angewandte Chemie 2011, 123 (37), 8890–8893. DOI:https://doi.org/10.1002/anie.201102946

5. Akamatsu, K.; Kanasugi, S.; Nakao, S.-I.; Weitz, D. A. "Membrane-Integrated Glass Capillary Device for Preparing SmallSized Water-in-Oil-in-Water Emulsion Droplets." Langmuir 2015, 31 (25), 7166–7172. DOI:https://doi.org/10.1021/acs.langmuir.5b01514

6. Okushima, S.; Nisisako, T.; Torii, T.; Higuchi, T. "Controlled Production of Monodisperse Double Emulsions by Two-Step Droplet Breakup in Microfluidic Devices." Langmuir 2004, 20 (23), 9905–9908.DOI:https://doi.org/10.1021/la0480336