3D printing - Jianlin Zhou

History

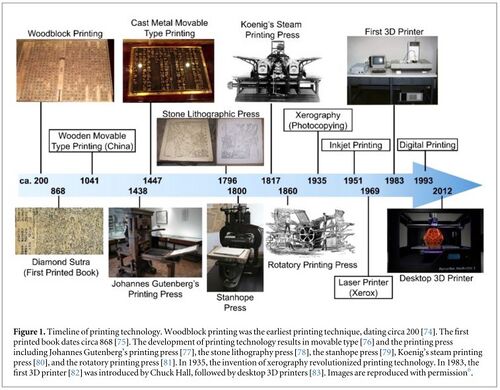

The concept of printing is the creation of a pattern of certain detention, which eliminated the use of mold. In the case of 3D printing, it is opposition to casting or injection molding. The first 3D printing method, stereolithography (SLA), was invented by Charles W. Hull in 1986[1]. In 1989, S. Scott and Lisa Crump patented their invention of fused deposition modeling (FDM), which feeds a plastic filament into a heated extruder and precisely lays down the heated material, and co-founded Stratasys, Ltd[2]. The methods above are also called additive manufacturing. In the early 1990s, a series of patents were filed for early versions of powder sintering printing technologies. These patents became the core technology of Z Corp, which later was acquired by 3D Systems[2]. With the assist of Computer Aided Design (CAD), various 3D printing technologies became more capable of manufacturing complex structures and more widely commercialized.

Since then, development and innovation in the field has occurred at an increasingly rapid pace. Novel technologies include two-photon polymerization[3], which can print at the molecular level as well as contour crafting[4], which makes it possible to print large-scale concrete structures. Other technologies include food printing and bioprinting which could make it possible to print out human organs. Furthermore, the expiration of many early 3D printing patents has allowed the general public to co-opt additive manufacturing, which catalyzed the start of the RepRap movement, which is the open-source arm of the 3D printing movement[2].

Overview

The printing of solid structure involves the temporary phase change of the miniscule raw materials. Depend on the on the number of the nature of the phase change, 3D printing can be classified into two categories:

- Physical process

The phase changes within the process utilized the melting point or melting temperature of the material. The printer first melts the filament into liquid letting it adhere to the desired position of the prior layer(s). Then, the material would be cooled back into solid phase which is the final form of the print.

- Chemical process

In general, its material is a monomer or oligomer solution. Polymerization reaction is used to transform the solution into solid polymer initiated by the photo-initiator. It also requires post processing, which is washing away the leftover monomer solution on the print.

There are three steps of polymerization[5]:

- Initiation: The initiator molecules in the photopolymer solution forms free radicals under UV light beam. The free radical, act as a starting point of the polymerization, combines with a monomer or oligomer, forming a radicalized monomer.

- Propagation: The monomers and oligomers surrounded then attach to the radicalized end of the propagating molecule. However, in the case of resin printing, cross-linking is the main mechanism, which provides monomers or oligomers multiple radical sites for prorogation.

- Termination: As the access of free radicals become limited, the newly formed polymer molecules with radical end would connect one another, then the entire polymerization reaction ends.

Categories

There are many different technologies to do 3D printing. Since 2010, the American Society for Testing and Materials (ASTM) carried out the “ASTM F42 – Additive Manufacturing” standards, which classifies the additive manufacturing processes into 7 categories[6].

- Vat Photopolymerization

- Stereolithography (SLA)

- Digital Light Processing (DLP)

- Continuous Liquid Interface Production (CLIP)

- Material Jetting

- Binder Jetting

- Material Extrusion

- Fused Deposition Modeling (FDM)

- Fused Filament Fabrication (FFF)

- Contour Crafting

- Powder Bed Fusion

- Selective Laser Sintering (SLS)

- Direct Metal Laser Sintering (DMLS)

- Sheet Lamination

- Directed Energy Deposition

Fused Deposition Modeling (FDM)

This is the most common and mainstream 3D printing method. Consumer-level 3D extrusion printers are available and very inexpensive; they have many options in the range of just a few hundred dollars. It is an additive process where the object is created by placing melted material layer by layer in a path; thermoplastic polymers are the most common materials due to their ability to quickly melt and cool[7]. This method allows for a myriad of materials to be used. Theoretically, any material that can be melted and cooled to a solid can be used with extrusion 3D printing.

For this process, the material is loaded into the printer, and it is passed on to the extrusion head once the nozzle reaches the correct temperature; the material melts in the nozzle, but the extrusion head allows the layers to be formed in any pattern. The strands are printed layer by layer, and they then cool ultimately creating a solid product. The platform moves down once the layer is complete in order to create a new layer which repeats until the object is done[7].

One drawback of this method as it applies to microfluidics is the resolution of these extrusion printers is typically not low enough to be effective for microfluidic channels, although recent improvements have placed resolution down to the micrometer scale[8]. Additionally, during printing in this method, it is very difficult to get the layers to line up perfectly, making it difficult for this method to contain fluids.

In order to compensate for this drawback, there are several options available for finishing 3D models made using this technique such as exposing the model to a higher temperature so as to re-melt the layers together for a better fit or using an appropriate chemical gas to partially dissolve the exposed outer layers and smooth them together. Current “affordable” 3D printers can achieve resolutions around 50 microns[9].

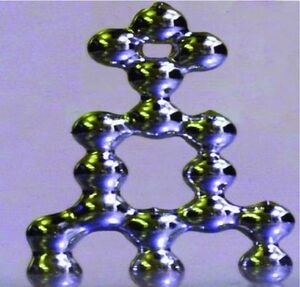

An example technique which has potential to make this method more specific to microfluidic structures is described by Ladd et al[10]. This research is particularly interesting because this printing occurs at room temperature. A gallium and indium ally with an oxide over layer was able to be extruded through a needle to achieve a resolution of approximately 8 mm. The researchers were able to create wires, arrays of spheres, arches and interconnects.

3D Printing of Polylactic Acid

Polylactic acid (PLA) is one of the most commonly used plastics for (FDM) 3D printing. It is a biodegradable polymer which is produced from the bacterial fermentation of plants such as corn, potato, or cassava. It is approved by the USDA for food contact, so it is potentially food safe[11]. In reality, there are other aspects inherent to the 3D printing process, such as the metal nozzle (which may or may not be food safe and could contain metal contaminants such as lead) or small crevices which are difficult to clean both creating complications for 3D printing with food products. Another beneficial aspect of this polymer is the fact that it can be created into complex shapes; this is the reason it is commonly used for bone fixation and reconstruction[12]. It is a great source for medical implants, orthopedic devices, and tissue engineering due to its strong durability and cheap cost. The fact that it is thermoplastic and biodegradable is also a plus because it has mechanical strength and good biocompatibility[13]. In addition, by using transparent filament and adequate post processing, 3D printing of PLA can be beneficial for microfluidic device manufacturing.

Stereolithography (SLA)

Stereolithography (SLA) is categorized into the vat photopolymerisation group by ASTM, which was introduced in 1982 by Chuck Hull[14]. Although the most commercially available type of printing style is Fused Deposition Modeling (FDM), it generally has poor printing resolution. In addition, the FDM printed parts have large void space and adhesion quality irregularity. Transparency and high resolution are fundamental for microfluidic applications. In some cases, certain rigidity is critical as well. Under such restrictions, the Stereolithography (SLA) suits the best, by using the commercially available clear resin from FormLabs. Its current SLA 3D printer have the xy-axis resolution of 25 μm[15]. Compared to the limitation of printing PDMS, the use of clear resin and Formlab SLA printer is highly competitive[9] [5].

Upon printing, a thin layer of photopolymer solution is targeted by the light sources which can be a scanning laser or a digital light projector (DLP)[16]. Based on the printing part, the light source would trace the desired 2D cross section pattern. The photo-initiator would respond and initiate the polymerization reaction locally. After the entire 2D pattern were traced, the platform will be raised or lowered, depending on the printing style, allowing new layer to be printed. Then, the printing cycle continues until completion[17] [5].The photopolymer solution contains monomer, oligomer, and photo-initiator [16] [18].Based on the clear resin printing technology, the raw materials of the solution are Urethane dimethacrylate (UDMA), Methacrylate Monomer(s) and Diphenyl(2,4,6-trimethylbenzoyl)phosphine oxide[19].

Selective Laser Sintering (SLS)

References

- ↑ Lerner, K. L. 3D Printing. in The Gale Encyclopedia of Science 4383 (Gale, 2014).

- ↑ 2.0 2.1 2.2 Horvath, J. A Brief History of 3D Printing. in Mastering 3D Printing 3–10 (Apress, 2014).

- ↑ Cumpston, B. H. et al. Two-photon polymerization initiators for three dimensional optical data storage and microfabrication. Nature 398, 51–54 (1999).

- ↑ Khoshnevis, B. & Epstein, D. J. Automated construction by contour crafting-related robotics and information technologies. doi:10.1016/j.autcon.2003.08.012

- ↑ 5.0 5.1 5.2 Mendes‐Felipe, C., Oliveira, J., Etxebarria, I., Vilas‐Vilela, J. L., & Lanceros‐Mendez, S. (2019). State‐of‐the‐art and future challenges of UV curable polymer‐based smart materials for printing technologies. Advanced Materials Technologies, 4(3). https://doi.org/10.1002/admt.201800618

- ↑ What is 3D Printing, https://3dprinting.com/what-is-3d-printing/ (accessed May 4th)

- ↑ 7.0 7.1 Galicia J, Benes B. Improving printing orientation for Fused Deposition Modeling printers by analyzing connected components. Additive Manufacturing 2018; vol 22: 720-28. DOI:https://doi.org/10.1016/j.addma.2018.06.007

- ↑ A. A. Yazdi, A. Popma, W. Wong, T. Nguyen, Y. Pan, and J. Xu, “3D printing: an emerging tool for novel microfluidics and lab-on-a-chip applications,” Microfluid. Nanofluidics, vol. 20, no. 3, p. 50, Mar. 2016. DOI: https://doi.org/10.1007/978-3-319-40036-5_4

- ↑ 9.0 9.1 Comina, G., Suska, A., & Filippini, D. (2014). PDMS lab-on-a-chip fabrication using 3D printed templates. Lab on a Chip, 14(2), 424-430. https://doi.org/10.1039/c3lc50956g

- ↑ C. Ladd, J.-H. So, J. Muth, and M. D. Dickey, “3D Printing of Free Standing Liquid Metal Microstructures,” Adv. Mater., vol. 25, no. 36, pp. 5081–5085, Sep. 2013. DOI: https://doi.org/10.1002/adma.201301400

- ↑ R. Auras, “Poly(lactic acid,” 2010, John Wiley & Sons, Inc. DOI: https://doi.org/10.1002/0471440264.pst275

- ↑ Giordano R, Wu B, Borland S, Cima L. Mechanical properties of dense polylactic acid structures fabricated by three dimensional printing. Journal of Biomaterials Science 1997; vol 8, no 1: 63-75. DOI:https://doi.org/10.1163/156856297X00588

- ↑ Saini P, Arora M, Kumar MNVR. Poly(lactic acid) blends in biomedical applications. Adv Drug Deliv Rev 2016; 107: 47-59. DOI: 10.1016/j.addr.2016.06.014

- ↑ Amin R, Knowlton S, Hart A et al. 3D-printed microfluidic devices. Biofabrication 2016;8, DOI:10.1088/1758-5090/8/2/022001

- ↑ Materials Library. https://formlabs-media.formlabs.com/filer_public/ac/89/ac8963db-f54a-4cac-8fe9-fb740a7b06f1/formlabs-materials-library.pdf (accessed 3/27/2022)

- ↑ 16.0 16.1 Waheed, S., Cabot, J. M., Macdonald, N. P., Lewis, T., Guijt, R. M., Paull, B., & Breadmore, M. C. (2016). 3D printed microfluidic devices: enablers and barriers. Lab on a Chip, 16(11), 1993-2013. https://doi.org/10.1039/C6LC00284F

- ↑ Nielsen, Anna V., et al. "3D printed microfluidics." Annual Review of Analytical Chemistry 13 (2020): 45-65.https://doi.org/10.1146/annurev-anchem-091619-102649

- ↑ Yang, W., Yu, H., Liang, W., Wang, Y., & Liu, L. (2015). Rapid fabrication of hydrogel microstructures using UV-induced projection printing. Micromachines, 6(12), 1903-1913. https://doi.org/10.3390/mi6121464

- ↑ Clear Resin; MSDS No. FLGPCL04[Online]; Formlabs, Inc: Somerville, MA, February 25, 2020. https://formlabs-media.formlabs.com/datasheets/1801037-SDS-ENEU-0.pdf(accessed 3/27/2022)