User:Andy Maloney/Notebook/Lab Notebook of Andy Maloney/2009/02/19/Optical tweezers

After brainstorming with everyone in the lab, we have come up with the components necessary to make our optical tweezers work. There is no way I am going to be able to list everything we decided today in my notebook so I would have thought that this entry would be useless without my ability to make it comprehensive. However, Anthony has shown me the light when it comes to organization on the wiki and today starts my first open notebook session. Below is a list of things we would like to have for our optical tweezers.

Diode laser

The laser is the most crucial part of an optical tweezers because it is what you use to tweeze things with. I have written a brief description of how to build your own diode laser using off the shelf OEM parts purchased from Thorlabs. The write up can be found here with a parts list here.

The controller we purchased has the capability to control a 1 Watt laser diode and the ability to control a peltier cooler. The diode I've priced out comes from PLT Technology. It's a 1 W 690 nm laser diode in a 9 mm can package. While we purchased one from this company, we haven't received it yet. I have tried to get in touch with the person in charge of our order, but they are stubbornly ignoring me. I think I would very much like to not recommend this company for laser diodes in the future. While they may be cheap, the customer service is terrible and not worth the worry to order from them again.

I have found this company. I sent a quote asking for a 690 nm, 1.2 W diode in the 9 mm package. We will see what happens.

- Optical isolator

- Beam shaping

- Spatial filtering

- Telescopes

Sample translation stage

Our sample stage is custom built using parts purchased from optomechanics companies like Thorlabs and Newport. We had to modify the main stage so that we could attach it to our microscope.

An important reason as to why one would want to mount a stage directly to the microscope is because of vibrations. Apparently you can use the magic hand waving argument about neglecting vibrations if everything you use to detect the sample is connected to one another, i.e. how a stage is attached to the microscope. Something about common mode vibration but that is the extent of my knowledge in the subject.

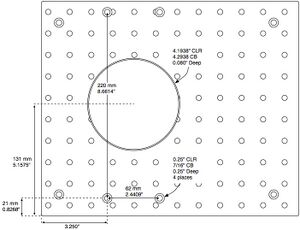

With that said, we wanted the stage to be customizable and have the ability to attach other optics to it. This lead us to using an aluminum breadboard modified so that it would fit on the microscope. One very nice thing about this plate is that it allows the microscope to retain all its microscopy functionality and it is unobtrusive.

So from my understanding with optical tweezers you want to have the ability to "steer" your beam. There are 3 possibilities to do this and they include: moving the lens of a telescope, using an optical deflector, or using a piezo stage. Using a telescope has the possibility of introducing aberrations and an optical deflector are expensive and they mess with beam quality. So, we opted for using a piezo stage with sub nanometer resolution from Mad City Labs. Going with this option means that we had to design a platform for the PZ to sit on. Again, we used pre-made parts to do this. Originally a design was made to create our own parts but it ended up not fitting properly on the microscope thus wasting lots of man hours machining. This is why I am all about not machining except as a the last resort. You will be surprised to realize that most everything you need to build can be purchase from lots of different companies.

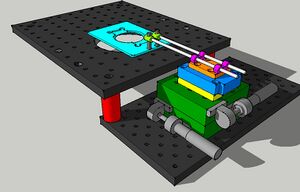

At any rate, the new design ended up using the original design idea which uses a ledge to hold the PZ off of the microscope plate. Below you can see my 3D model of our Sample Translator Plate.

All items save one shown can be purchase from different companies so there is minimal machining involved. The only part that needed to be fully made was the orange one. The yellow one is a modified baseplate from Newport that we only needed to tap 4 holes in. I can't find my diagram for the part I had to completely machine, but once I do find it, I'll post it.

Parts List

| Component | Model Number | Cost | # Needed | CAD Drawing | Sketchup |

| 10" x 12" breadboard | MB1012 | $164.60 | 1 | Yes | Yes |

| 6" x 12" breadboard | MB612 | $124.00 | 1 | Yes | Yes |

| ø1" x 2" posts | RS2 | $20.00 | 2 | Yes | Yes |

| ø1" x 0.12" spacer | RS01 | $6.80 | 2 | Yes | Yes |

| 1" translation stage | 426 | $428.40 | 2 | Yes | Yes |

| I used only the top baseplate and tapped 4 holes in it | MB-3 | $72.42 | 1 | Yes | [Not yet] |

| PZ stage | Nano-OP30 | A lot! | 1 | Yes | Yes |

| [Orange part] | Awesome | Nothing but time | 1 | [Not yet] | [Not yet] |

| Diving board rod holder | SMB1 | $15.50 | 2 | Yes | Yes |

| ø3 mm x 6" rods | SR6 | $8.70 | 2 | Yes | [No] |

| ø6 mm x 1" rods | ER1 | $5.18 | 2 | Yes | [No] |

| Right angle rod holder | ER90B | $12.40 | 2 | Yes | Yes |