CHEM-ENG590E Wiki Textbook:Microcontact Printing: Difference between revisions

| Line 42: | Line 42: | ||

<div align="center"> | <div align="center"> | ||

<gallery heights=200px widths=400px perrow="2"> | <gallery heights=200px widths=400px perrow="2"> | ||

Image: Fabricated nanocantilever array.png|'''Figure 4.''' Salomon et al. fabricated an array of nanocantilevers on the scale of 10<sup>5</sup> | Image: Fabricated nanocantilever array.png|'''Figure 4.''' Salomon et al. fabricated an array of nanocantilevers on the scale of 10<sup>5</sup> nanocantilevers/cm<sup>2</sup>. | ||

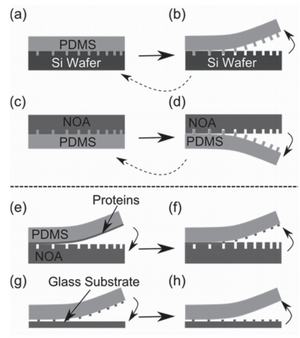

Image: IgGandBSAPrinting.png|'''Figure 5.''' Two methods of printing were used, resulting in both inked surfaces of BSA underneath the cantilevers and solely around the cantilevers. (1) Inking the stamp with IgG. (2) Washing and drying the stamp. (3) Cleaning outside the stamp grooves. (3B) Inking the stamp with BSA. (4) Printing after aligning the stamp and the chip. (4A) Incubating the chip with BSA. (5) Result. | Image: IgGandBSAPrinting.png|'''Figure 5.''' Two methods of printing were used, resulting in both inked surfaces of BSA underneath the cantilevers and solely around the cantilevers. (1) Inking the stamp with IgG. (2) Washing and drying the stamp. (3) Cleaning outside the stamp grooves. (3B) Inking the stamp with BSA. (4) Printing after aligning the stamp and the chip. (4A) Incubating the chip with BSA. (5) Result. | ||

</gallery> | </gallery> | ||

Revision as of 16:52, 15 April 2016

Microcontact Printing

Microcontact printing (MCP) is a technique of patterning that utilizes soft lithography to create a polydimethylsiloxane (PDMS) "stamp" in order to print micro-scale patterns. The concept of microcontact printing was first published in a 1993 paper written by George Whitesides and Amit Kumar of Harvard University. Their original goal was to use microcontact printing for micromachining. Since then, microcontact printing has been used for a variety of applications from biomaterial patterning to micro electronics.[2]

Procedure

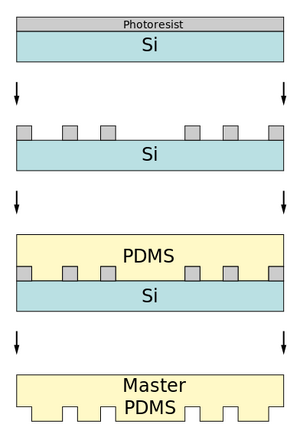

Prepare Etched Silicon Master and PDMS Stamp

Using standard photolithography techniques, a silicon master must be created. A PDMS stamp can then be created with soft lithography. The silicon master can be reused to create multiple stamps, and each stamp can be used for multiple stampings.

Ink Stamp and Apply Stamp to Substrate

The PDMS stamp is dipped into the "ink" of interest, and then applied to the substrate. Inking and stamping times vary depending on the properties of the ink and substrate.

Advantages

- Relatively cheap and simple process

- Minimal cleanroom time (only necessary to create the etched master)

- Multiple stamps can be created from a single etched master

- Reusable stamps

- Possibility to be scaled up and automate parts of the process

- Printing requires less “ink” than flow coating for patterning

- Can print on non-flat surfaces

Applications

Micromachining[2]

Microcontact printing originates with research in micromachining applications by Whitesides et al. The Whitesides Group demonstrated a novel form of microfabrication by printing self-assembled monolayers, or SAMs, of alkanethiol (a common 'ink') on a gold support (a common substrate). The ink then acted as a form of photoresist in wet etching of the gold substrate by protecting the gold from corrosion caused by the etchants. Additional complex etching methods may be employed to further achieve high resolution microstructures. The true value of this method is that it avoids the repeated use of traditional photolithographic techniques in micromachining. The Whitesides Group also demonstrated that microcrystal arrays were capable of being fabricated using this novel microcontact printing approach.

Biomaterial Patterning[5]

Cell-cell interactions may be studied using micropatterning techniques like printing. Bhatia et al. demonstrated that microcontact printing allowed spatial control over liver cell populations, and thus allowed a highly sophisticated method of investigation of cell growth, movement, shape, and death. In this study, collagen structures were immobilized under a patterned photoresist mask. The collagen then acted as an adhesive extracellular matrix for a patterning of hepatocytes and nonparenchymal cells. The cell interactions in this microenvironment were then studied.

Biosensors[11]

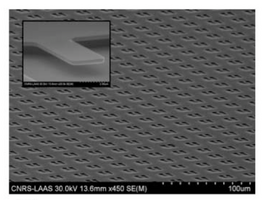

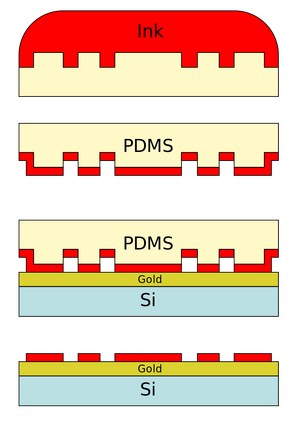

Microcontact printing has also been employed in biosensor fabrication. Salomon et al. demonstrated precise printing of an antibody IgG and an antifouling compound BSA on a nanocantilever structure array. Cantilevers are a common structure used in biosensors, and an array of nanocantilevers allows for high selectivity and precise detection. The IgG was printed on the nanocantilevers, while the BSA was printed underneath and around the nanocantilevers.

-

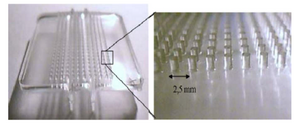

Figure 4. Salomon et al. fabricated an array of nanocantilevers on the scale of 105 nanocantilevers/cm2.

-

Figure 5. Two methods of printing were used, resulting in both inked surfaces of BSA underneath the cantilevers and solely around the cantilevers. (1) Inking the stamp with IgG. (2) Washing and drying the stamp. (3) Cleaning outside the stamp grooves. (3B) Inking the stamp with BSA. (4) Printing after aligning the stamp and the chip. (4A) Incubating the chip with BSA. (5) Result.

Challenges of Microcontact Printing

Several challenges arise during microcontact printing, most of which will lead to poor ink or pattern transfer due to distortions of the stamp pattern.

- Stamp deformation

Deformation of the PDMS stamp can occur at all steps of fabrication, but is most likely to occur during removal from the master, during transportation, or while contacting the substrate. Direct contact of the stamp with the substrate, when carried out with excess vertical pressure, can cause deformations in both raised and entrenched features due to flattening or buckling. Excess stretching or compressing of the stamp may also lead to deformations such as microfractures, which may actually be smaller than the feature sizes. When designing the stamp master, it is important to consider the aspect ratio of the device. If the aspect ratio of the stamp is too low - the stamp features are too wide relative to their height - the features of the stamp can buckle in on themselves. If the aspect ratio of the stamp is too high - the stamp features are too tall relative to their width - the roof of the stamp can collapse.

- Pairing

Similar to roof collapse, pairing can occur due to a high stamp aspect ratio, specifically narrow feature roofs. Adhesive forces between the interface of adjacent features can cause them to pair up and deform the stamp pattern. Delamarche et al. studied the stability of PDMS microstructures[12], and they proposed that during drying of the stamp for wet inking, the receding solvent meniscus induced local capillary forces driving the microstructures together.

- Stamp volume defects (shrinking or swelling)

Volume defects of the stamp are common in microcontact printing. Shrinking can occur during the curing process, and results in a PDMS stamp differing slightly in size from the master. Use of organic solvents during wet inking can cause swelling. Ethanol is a commonly used solvent as its swelling effect is minimal.

- Ink mobility

Vapor phase diffusion and surface diffusion of the ink can occur during contact with the substrate, and may lead to ink spreading into undesirable regions of both the stamp and the substrate. Resulting patterns typically have low or poor resolution and may look splotchy or warped if the ink diffusion is high.

Cutting Edge Techniques

Magnetic Field Printing[9]

Cau et al. demonstrated that perfect reproducibility and homogeneous pressure is capable by magnetic field printing. By creating a second layer of PDMS injected with iron powder, the stamp was able to be manipulated using fully automated equipment utilizing a magnetic field. The field maintains the position of the whole PDMS stamp via the iron powder, and can be adjusted for the size of the stamp features (i.e. decreasing the strength of the magnetic field for larger features to allow some margin of movement and prevent feature damage).

High-Speed Printing[6]

Submerged Printing[7]

This technique attempts to address some of the stamp deformation issues by performing stamping within a non-compressible fluid. Bessueille et al. have shown that by stamping in a liquid, a much greater pressure can be applied to the stamp without deforming the pattern. additionally, higher aspect ratio features can be stamped. While conventional microcontact printing shows serious deformation over a ratio of 10:1, when submerged, a 46:1 ratio transfers perfectly, and ratios as high as 83:1 are still highly functional.

Liftoff Printing[8]

Liftoff printing is a technique that is intended to compensate for printing flaws caused by overly large aspect ratios. The technique was first used by Ricoult et al. to create an array of microdots which could not have been printed using conventional means. Instead of creating a stamp with an array of posts to print the dots, the team created a negative stamp, coated a flat piece of PDMS with their ink, and then lifted off the unwanted ink using the negative stamp. This left ink on the PDMS only in the micro dot array. This technique can be applied in similar situations where conventional stamping methods would fail.

Macro-Stamping[10]

Macro-Stamping is a technique developed by H. Lalo et al. which utilized a titration plate to create an array of micro dots of different ink. A stamp was created with an array of mili scale posts. The array was designed to be dipped into a titration plate and have each post go into a single well. The ends of the posts had micro scale dot arrays. By filling different wells in the plate with different ink, a macro array of micro arrays of different ink can be rapidly and repeatedly stamped.

References

1. Kaufmann, T.; Ravoo, B. J. Stamps, inks and substrates: polymers in microcontact printing. Polymer Chemistry. 2010, 1 (4), 371.

2. Wilbur, J. L.; Kumar, A.; Biebuyck, H. A.; Kim, E.; Whitesides, G. M. Microcontact printing of self-assembled monolayers: applications in microfabrication. Nanotechnology. 1996, 7 (4), 452–457.

3. Cau, J.; Lafforgue, L.; Nogues, M.; Lagraulet, A.; Paveau, V. Magnetic field assisted microcontact printing: A new concept of fully automated and calibrated process. Microelectronic Engineering. 2013, 110, 207–214. http://www.biosoftlab.com/index.php/biosoft-technologies/soft-lithography

4. Gross, G. W., et al. The use of neuronal networks on multielectrode arrays as biosensors. Biosensors and Bioelectronics. 1995, 70 (6-7), 553-567.

5. Bhatia, S.; Balis, U.; Yarmush, M.; Toner, M. Effect of cell-cell interactions in preservation of cellular phenotype: cocultivation of hepatocytes and nonparenchymal cells. Faseb Journal. 1999, 13 (14), 1883-1900.

6. Helmuth, J.; Schmid, H.; Stutz, R.; Stemmer, A.; Wolf, H. High-Speed Microcontact Printing. J. Am. Chem. Soc. 2006, 128 (29), 9296–9297.

7. Bessueille, F.; Pla-Roca, M.; Mills, C.; Martinez, E.; Samitier, J.; Errachid, A. Submerged Microcontact Printing (SμCP): An Unconventional Printing Technique of Thiols Using High Aspect Ratio, Elastomeric Stamps. Langmuir. 2005, 21 (26), 12060–12063.

8. Ricoult, S.; Pla-Roca, M.; Safavieh, R.; Lopez-Ayon, G.; Grütter, P.; Kennedy, T.; Juncker, D. Large Dynamic Range Digital Nanodot Gradients of Biomolecules Made by Low-Cost Nanocontact Printing for Cell Haptotaxis. Small. 2013, 9 (19), 3308–3313.

9. Cau, J.; Lafforgue L.; Nogues M.; Lagraulet, A.; Paveau, V. Magnetic field assisted microcontact printing: A new concept of fully automated and calibrated process. Microelectronic Engineering. 2013, 110, 207–214.

10. Lalo, H.; Cau, J.; Thibault, C.; Marsaud, N.; Severac, C.; Vieu, C. Microscale multiple biomolecules printing in one step using a PDMS macrostamp. Microelectronic Engineering. 2009, 86 (4–6), 1428–1430.

11. Salomon, S.; Leïchlé, T.; Dezest, D.; Seichepine, F.; Guillon, S.; Thibault, C.; Vieu, C.; Nicu, L.. Arrays of nanoelectromechanical biosensors functionalized by microcontact printing. Nanotechnology. 2012, 23 (49).

12. Delamarche, E.; Schmid, H.; Michel, B.; Biebuyck, H. Stability of molded polydimethylsiloxane microstructures. Adv. Mater. 1997, 9, 741–746.