CHEM-ENG590E Wiki Textbook:Microcontact Printing: Difference between revisions

| Line 51: | Line 51: | ||

'''Submerged Printing<sup>[7]</sup>''' | '''Submerged Printing<sup>[7]</sup>''' | ||

This technique attempts to address some of the stamp deformation issues by performing stamping within a non-compressible fluid. Bessueille et al. have shown that by stamping in a liquid, a much greater pressure can be applied to the stamp without deforming the pattern. additionally, higher aspect ratio features can be stamped. While conventional microcontact printing shows serious deformation over a ratio of 10:1, when submerged, a 46:1 ratio transfers perfectly, and ratios as high as 83:1 are still highly functional. | This technique attempts to address some of the stamp deformation issues by performing stamping within a non-compressible fluid. Bessueille et al. have shown that by stamping in a liquid, a much greater pressure can be applied to the stamp without deforming the pattern. additionally, higher aspect ratio features can be stamped. While conventional microcontact printing shows serious deformation over a ratio of 10:1, when submerged, a 46:1 ratio transfers perfectly, and ratios as high as 83:1 are still highly functional. | ||

'''Liftoff Printing<sup>[8]</sup>''' | '''Liftoff Printing<sup>[8]</sup>''' | ||

[[Image:Liftoff Printing Procedure.png|right|thumbnail|'''Figure X''' Liftoff printing procedure <sup>[8]</sup>]] | [[Image:Liftoff Printing Procedure.png|right|thumbnail|'''Figure X''' Liftoff printing procedure <sup>[8]</sup>]] | ||

Liftoff printing is a technique that is intended to compensate for printing flaws caused by overly large aspect ratios. The technique was first used by Ricoult et al. to create an array of microdots which could not have been printed using conventional means. Instead of creating a stamp with an array of posts to print the dots, the team created a negative stamp, coated a flat piece of PDMS with their substrate, and then lifted off the unwanted substrate using the negative stamp. This left substrate on the PDMS only in the micro dot array. This technique can be applied in similar situations where conventional stamping methods would fail. | |||

'''Macro-Stamping<sup>[10]</sup>''' | '''Macro-Stamping<sup>[10]</sup>''' | ||

Revision as of 17:44, 13 April 2016

Microcontact Printing

Microcontact printing (MCP) is a technique that utilizes soft lithography to create a polydimethylsiloxane (PDMS) "stamp" in order to print micro-scale patterns. The concept of microcontact printing was first published in a 1993 paper written by George Whitesides and Amit Kumar of Harvard University. Their original goal was to use microcontact printing for micromachining. Since then, microcontact printing has been used for a variety of applications from biomaterial patterning to micro electronics.[2]

Procedure

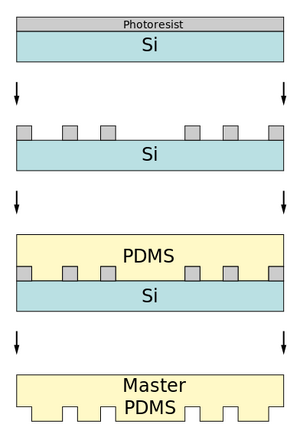

Prepare Etched Silicon Master

Using standard photolithography techniques, a silicon master must be created.

Create PDMS Stamp

Ink Stamp

Apply stamp to substrate

Advantages

- Relatively cheap and simple process

- Minimal cleanroom time (only necessary to create the etched master)

- Multiple stamps can be created from a single etched master

- Reusable stamps

- Possibility to be scaled up and automate parts of the process

- Printing requires less “ink” than flow coating for patterning

- Can print on non-flat surfaces

Applications

Micromachining[2]

Biomaterial Patterning[5]

Biosensors[11]

Challenges of Microcontact Printing

- Stamp deformation

- Buckling

- Pairing

- Roof Collapse

- Contamination of substrate

- Stamp volume defects (shrinking or swelling)

- Ink mobility

Cutting Edge Techniques

Magnetic Field Printing[9]

High-Speed Printing[6]

Submerged Printing[7]

This technique attempts to address some of the stamp deformation issues by performing stamping within a non-compressible fluid. Bessueille et al. have shown that by stamping in a liquid, a much greater pressure can be applied to the stamp without deforming the pattern. additionally, higher aspect ratio features can be stamped. While conventional microcontact printing shows serious deformation over a ratio of 10:1, when submerged, a 46:1 ratio transfers perfectly, and ratios as high as 83:1 are still highly functional.

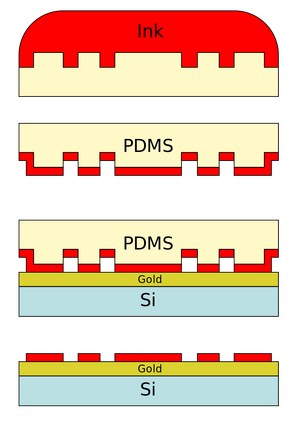

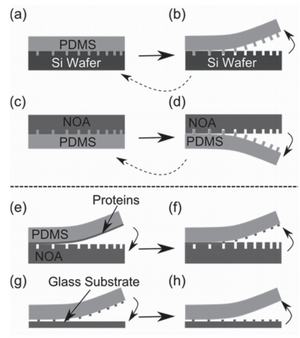

Liftoff Printing[8]

Liftoff printing is a technique that is intended to compensate for printing flaws caused by overly large aspect ratios. The technique was first used by Ricoult et al. to create an array of microdots which could not have been printed using conventional means. Instead of creating a stamp with an array of posts to print the dots, the team created a negative stamp, coated a flat piece of PDMS with their substrate, and then lifted off the unwanted substrate using the negative stamp. This left substrate on the PDMS only in the micro dot array. This technique can be applied in similar situations where conventional stamping methods would fail.

Macro-Stamping[10]

References

1. Kaufmann, T.; Ravoo, B. J. Stamps, inks and substrates: polymers in microcontact printing. Polymer Chemistry. 2010, 1 (4), 371.

2. Wilbur, J. L.; Kumar, A.; Biebuyck, H. A.; Kim, E.; Whitesides, G. M. Microcontact printing of self-assembled monolayers: applications in microfabrication. Nanotechnology. 1996, 7 (4), 452–457.

3. Cau, J.; Lafforgue, L.; Nogues, M.; Lagraulet, A.; Paveau, V. Magnetic field assisted microcontact printing: A new concept of fully automated and calibrated process. Microelectronic Engineering. 2013, 110, 207–214. http://www.biosoftlab.com/index.php/biosoft-technologies/soft-lithography

4. Gross, G. W., et al. The use of neuronal networks on multielectrode arrays as biosensors. Biosensors and Bioelectronics. 1995, 70 (6-7), 553-567.

5. Bhatia, S.; Balis, U.; Yarmush, M.; Toner, M. Effect of cell-cell interactions in preservation of cellular phenotype: cocultivation of hepatocytes and nonparenchymal cells. Faseb Journal. 1999, 13 (14), 1883-1900.

6. Helmuth, J.; Schmid, H.; Stutz, R.; Stemmer, A.; Wolf, H. High-Speed Microcontact Printing. J. Am. Chem. Soc. 2006, 128 (29), 9296–9297.

7. Bessueille, F.; Pla-Roca, M.; Mills, C.; Martinez, E.; Samitier, J.; Errachid, A. Submerged Microcontact Printing (SμCP): An Unconventional Printing Technique of Thiols Using High Aspect Ratio, Elastomeric Stamps. Langmuir. 2005, 21 (26), 12060–12063.

8. Ricoult, S.; Pla-Roca, M.; Safavieh, R.; Lopez-Ayon, G.; Grütter, P.; Kennedy, T.; Juncker, D. Large Dynamic Range Digital Nanodot Gradients of Biomolecules Made by Low-Cost Nanocontact Printing for Cell Haptotaxis. Small. 2013, 9 (19), 3308–3313.

9. Cau, J.; Lafforgue L.; Nogues M.; Lagraulet, A.; Paveau, V. Magnetic field assisted microcontact printing: A new concept of fully automated and calibrated process. Microelectronic Engineering. 2013, 110, 207–214.

10. Lalo, H.; Cau, J.; Thibault, C.; Marsaud, N.; Severac, C.; Vieu, C. Microscale multiple biomolecules printing in one step using a PDMS macrostamp. Microelectronic Engineering. 2009, 86 (4–6), 1428–1430.

11. Salomon, S.; Leïchlé, T.; Dezest, D.; Seichepine, F.; Guillon, S.; Thibault, C.; Vieu, C.; Nicu, L.. Arrays of nanoelectromechanical biosensors functionalized by microcontact printing. Nanotechnology. 2012, 23 (49).