CHEM-ENG590E Wiki Textbook:Microcontact Printing: Difference between revisions

| Line 2: | Line 2: | ||

==Microcontact Printing== | ==Microcontact Printing== | ||

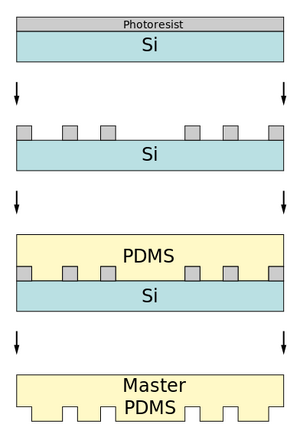

[[Image:Creating the PDMS master.svg.png|right|thumbnail]] | [[Image:Creating the PDMS master.svg.png|right|thumbnail|'''Figure 1''' Creating the PDMS master<https://commons.wikimedia.org/wiki/File:Creating_the_PDMS_master.svg>]] | ||

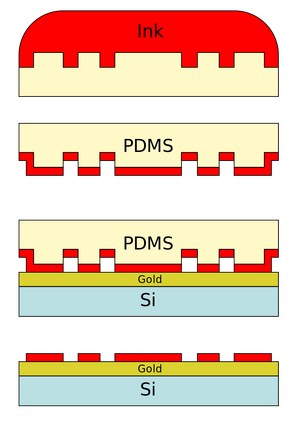

[[Image:Inking and contact process.png|right|thumbnail]] | [[Image:Inking and contact process.png|right|thumbnail|'''Figure 2''' Inking and stamping substrate<https://commons.wikimedia.org/wiki/File:Inking_and_contact_process.svg>]] | ||

Microcontact printing (MCP) is a technique that utilizes soft lithography to create a polydimethylsiloxane (PDMS) "stamp" in order to print micro-scale patterns. The concept of microcontact printing was first published in a 1993 paper written by George Whitesides and Amit Kumar of Harvard University. Their original goal was to use microcontact printing for micromachining. Since then, microcontact printing has been used for a variety of applications from biomaterial patterning to micro electronics.<sup>[2]</sup> | Microcontact printing (MCP) is a technique that utilizes soft lithography to create a polydimethylsiloxane (PDMS) "stamp" in order to print micro-scale patterns. The concept of microcontact printing was first published in a 1993 paper written by George Whitesides and Amit Kumar of Harvard University. Their original goal was to use microcontact printing for micromachining. Since then, microcontact printing has been used for a variety of applications from biomaterial patterning to micro electronics.<sup>[2]</sup> | ||

Revision as of 17:34, 13 April 2016

Microcontact Printing

Microcontact printing (MCP) is a technique that utilizes soft lithography to create a polydimethylsiloxane (PDMS) "stamp" in order to print micro-scale patterns. The concept of microcontact printing was first published in a 1993 paper written by George Whitesides and Amit Kumar of Harvard University. Their original goal was to use microcontact printing for micromachining. Since then, microcontact printing has been used for a variety of applications from biomaterial patterning to micro electronics.[2]

Procedure

Prepare Etched Silicon Master

Using standard photolithography techniques, a silicon master must be created.

Create PDMS Stamp

Ink Stamp

Apply stamp to substrate

Advantages

- Relatively cheap and simple process

- Minimal cleanroom time (only necessary to create the etched master)

- Multiple stamps can be created from a single etched master

- Reusable stamps

- Possibility to be scaled up and automate parts of the process

- Printing requires less “ink” than flow coating for patterning

- Can print on non-flat surfaces

Applications

Micromachining[2]

Biomaterial Patterning[5]

Biosensors[11]

Challenges of Microcontact Printing

- Stamp deformation

- Buckling

- Pairing

- Roof Collapse

- Contamination of substrate

- Stamp volume defects (shrinking or swelling)

- Ink mobility

Cutting Edge Techniques

Magnetic Field Printing[9]

High-Speed Printing[6]

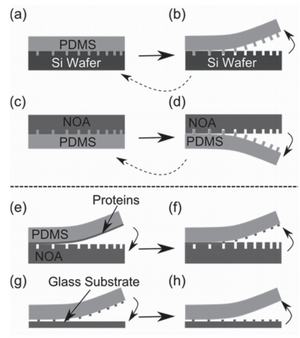

Submerged Printing[7] This technique attempts to address some of the stamp deformation issues by performing stamping within a non-compressible fluid. Bessueille et al. have shown that by stamping in a liquid, a much greater pressure can be applied to the stamp without deforming the pattern. additionally, higher aspect ratio features can be stamped. While conventional microcontact printing shows serious deformation over a ratio of 10:1, when submerged, a 46:1 ratio transfers perfectly, and ratios as high as 83:1 are still highly functional.

Liftoff Printing[8]

Macro-Stamping[10]

References

1. Kaufmann, T.; Ravoo, B. J. Stamps, inks and substrates: polymers in microcontact printing. Polymer Chemistry. 2010, 1 (4), 371.

2. Wilbur, J. L.; Kumar, A.; Biebuyck, H. A.; Kim, E.; Whitesides, G. M. Microcontact printing of self-assembled monolayers: applications in microfabrication. Nanotechnology. 1996, 7 (4), 452–457.

3. Cau, J.; Lafforgue, L.; Nogues, M.; Lagraulet, A.; Paveau, V. Magnetic field assisted microcontact printing: A new concept of fully automated and calibrated process. Microelectronic Engineering. 2013, 110, 207–214. http://www.biosoftlab.com/index.php/biosoft-technologies/soft-lithography

4. Gross, G. W., et al. The use of neuronal networks on multielectrode arrays as biosensors. Biosensors and Bioelectronics. 1995, 70 (6-7), 553-567.

5. Bhatia, S.; Balis, U.; Yarmush, M.; Toner, M. Effect of cell-cell interactions in preservation of cellular phenotype: cocultivation of hepatocytes and nonparenchymal cells. Faseb Journal. 1999, 13 (14), 1883-1900.

6. Helmuth, J.; Schmid, H.; Stutz, R.; Stemmer, A.; Wolf, H. High-Speed Microcontact Printing. J. Am. Chem. Soc. 2006, 128 (29), 9296–9297.

7. Bessueille, F.; Pla-Roca, M.; Mills, C.; Martinez, E.; Samitier, J.; Errachid, A. Submerged Microcontact Printing (SμCP): An Unconventional Printing Technique of Thiols Using High Aspect Ratio, Elastomeric Stamps. Langmuir. 2005, 21 (26), 12060–12063.

8. Ricoult, S.; Pla-Roca, M.; Safavieh, R.; Lopez-Ayon, G.; Grütter, P.; Kennedy, T.; Juncker, D. Large Dynamic Range Digital Nanodot Gradients of Biomolecules Made by Low-Cost Nanocontact Printing for Cell Haptotaxis. Small. 2013, 9 (19), 3308–3313.

9. Cau, J.; Lafforgue L.; Nogues M.; Lagraulet, A.; Paveau, V. Magnetic field assisted microcontact printing: A new concept of fully automated and calibrated process. Microelectronic Engineering. 2013, 110, 207–214.

10. Lalo, H.; Cau, J.; Thibault, C.; Marsaud, N.; Severac, C.; Vieu, C. Microscale multiple biomolecules printing in one step using a PDMS macrostamp. Microelectronic Engineering. 2009, 86 (4–6), 1428–1430.

11. Salomon, S.; Leïchlé, T.; Dezest, D.; Seichepine, F.; Guillon, S.; Thibault, C.; Vieu, C.; Nicu, L.. Arrays of nanoelectromechanical biosensors functionalized by microcontact printing. Nanotechnology. 2012, 23 (49).