Common 3D Printing Materials

Polylactic Acid (PLA)

Polylactic acid (PLA) is one of the most commonly used thermoplastics for 3D printing. It is a biodegradable polymer produced from the bacterial fermentation of plants such as corn, potato, or cassava, and it is potentially food safe with approval from the USDA for food contact.[1] Aspects inherent to the 3D printing process such as the nozzle containing metal contaminants or small crevices which are difficult to clean can cause complications with food products.

Another beneficial aspect of PLA is that it can be created into complex shapes. For instance, PLA is commonly used for bone fixation and reconstruction.[2] PLA's mechanical strength and strong durability, good biocompatibility, and cheap cost makes it a great material for medical implants, orthopedic devices, and tissue engineering. In addition, fibers can be spun and then turned into implants or other medical applications.[3]

Acrylonitrile Butadiene Styrene (ABS)

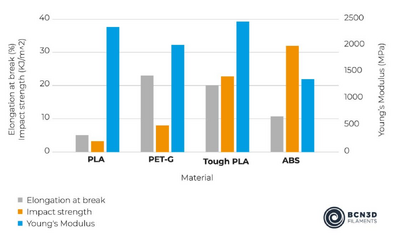

While Acrylonitrile Butadiene Styrene (ABS) can be a challenging material to print with, its applications and properties outside of 3D printing have made it an excellent material to use. ABS is a thermoplastic copolymer that can be heated and cooled to change from liquid to solid and vice versa without causing significant material degradation. ABS is known for its impact, chemical and heat resistance, with a high structural strength and great stiffness (Figure 1).[4]

Depending on the application, these properties make ABS desirable to work with in additive manufacturing to reduce waste and form parts from the ground up.[5] Examples of products containing ABS are kitchen appliances, auto dashboards, protective equipment, toys, musical instruments, and electrical equipment. The wide range of applications for ABS, mated with this excellent strength and resistance to weathering, make it a sensible material to 3D print.

One of the downsides to printing with ABS is its potential to warping and curling. ABS has a tendency to shrink up to 2% from cooling after the extrusion process.[5] Oftentimes, users may need to engage in a process of trial and error while adjusting the setup parameters to achieve the desired behavior in material extrusion. A build chamber that prevents cooling the material will be required for extrusion efficiency and for health and safety purposes. The addition of a fume extractor is essential for the chamber, as while the fumes may not be classified as toxic, they could cause physical discomfort such as eye irritation, nausea, and headaches.[6]

Polydimethylsiloxane (PDMS)

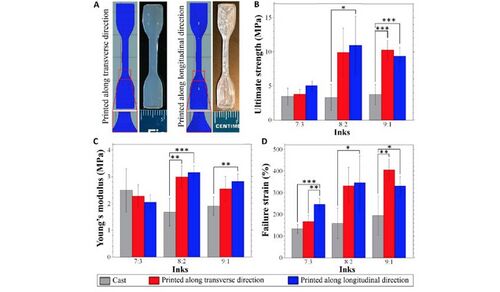

3D printing is widely used to print polydimethylsiloxane (PDMS) based microfluidic devices. 3D rapid prototyping fabrication technique maintains the desirable permeability and bio-compatibility of PDMS. The ink for 3D printing PDMS can be prepared by blending a shear thinning PDMS material, and a low-viscosity PDMS material. After desired mixing, the final PDMS inks were loaded into a syringe barrel at room temperature. Using a 3D bioprinter, different nozzle pressures, extrusion pressures, and printing speed can be controlled. Using this 3D printing technique, the PDMS object has higher mechanical properties in comparison to casting due to its decreased porosity and bubble entrapment (Figure 2).[7]

Bioprinting

Bioprinting is a 3D printing technique that allows for tissue-like structures to be created using biomaterials such as cells or growth factors.[8] Rather than using thermoplastic or PDMS, this process uses live cell suspension. Bioink is composed of living cells along with a compatible base which allows the cells to grow and have nutrients.[8]

The desired structure is created by depositing bioink layer by layer similarly to other methods of 3D printing. The amount of bioink deposited for each layer depends on the type of tissue that is being printed along with the number of nozzles. As the layers are added, the layer starts to solidify which is defined as crosslinking.[8] This type of 3D printing is used to imitate natural tissues, so it is most often in bioengineering and medical needs. It has also recently been used in reconstruction and regeneration of cartilage tissue.[8] In general, this method is extremely important when it comes to mimicking the environments of micro and macro tissues and organs which are used in clinical trials along with drug testing. Bioink allows for the product to be patient-specific since the patient's cells are being used.[8] In the future, bioprinting could be used to fabricate artificial organs for organ transplants or facilitate the repair of damaged tissues.

References

- Auras, R. A.; Lim, L.; Selke, S. E. M.; Tsuji, H. Poly(lactic Acid): Synthesis, Structures, Properties, Processing, Applications, and End of Life, John Wiley & Sons, Inc., 2010; DOI: https://doi.org/10.1002/0471440264.pst275

- Giordano, R. A.; Wu, B. M.; Borland, S. W.; Cima, L. G.; Sachs, E. M.; Cima, M. J. Mechanical properties of dense polylactic acid structures fabricated by three dimensional printing. Journal of Biomaterials Science. 1997; 8, pp 63-75; DOI: https://doi.org/10.1163/156856297X00588

- Saini, P.; Arora M.; Kumar, M. N. V. R. Poly(lactic acid) blends in biomedical applications. Advanced Drug Delivery Reviews 2016; 107, pp 47-59; DOI: https://doi.org/10.1016/j.addr.2016.06.014

- BCN3D: PLA vs Tough PLA. https://support.bcn3d.com/knowledge/pla-vs-tough-pla-bcn3d, 2023. https://support.bcn3d.com/knowledge/pla-vs-tough-pla-bcn3d

- MakerBot: Everything you need to know about ABS 3D printing, 2023. https://www.makerbot.com/stories/engineering/abs-3d-printing/

- Purex: The dangers of ABS Filament Fumes. https://www.purex.co.uk/blog/the-dangers-of-abs-filament-fumes/#:~:text=Although%20ABS%20filament%20fumes%20are,eye%20irritation%2C%20nausea%20and%20headaches, 2023

- Ozbolat V.; Dey M.; Ayan B.; Povilianskas, A.; Demirel, M. C.; Ozbolat, I. T. 3D Printing of PDMS Improves Its Mechanical and Cell Adhesion Properties. ACS Biomater. Sci. Eng. 2018 4(2), 682–693; DOI: https://doi.org/10.1021/acsbiomaterials.7b00646

- Atala, A.; Murphy, S. V. 3D bioprinting of tissues and organs. Nature Biotechnology, 2014 32, pp 773-785; DOI: https://doi.org/10.1038/nbt.2958