Commercialized Microfluidics - Fluidigm - Jashan Achpalia

Fluidigm

Fluidigm Corporation is a publicly-traded, American company that engages in selling biological research equipment based on its integrated fluidic technology. Their products have been cutting edge in the application of protein crystallization, genotyping, DNA analysis, and PCR. Headquartered in South San-Francisco, Fluidigm has offices in North America, Europe, Asia, and Australia [1]. Fluidigm was founded in 1999 as “Mycometrix” by Stephen Quake, Ph.D. and Gajus Worthington. Quake's research group in Stanford developed Multilayer Soft Lithography [5], this formed the proprietary technology that allowed Fluidigm to develop its Integrated Fluidic Devices (IFC). Fluidigim completed an initial public offering on February 2011 under the ticker symbol of FLDM, raising upto 75 million dollars [2]. On 2016, Worthington stepped down as president and CEO, and Chris Linthwaite was appointed instead.

Patented Technologies and Processes

Multilayer Soft Lithography

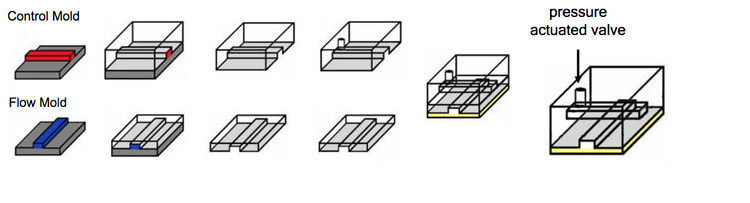

Multilayer Soft Lithography uses rubber as a base material and a series of channels transected by control lines. When pressurized, the control lines create an effective seal that allows for small structures and a dense network of channels to be fabricated on to a microfluidic device. The dense network of channels allows regulation of solutions and reagents in the micro-, nano- or even picoliter scale. The process begins by using a flat panel display (FPD) to generate mold features using a patterned photoresist, the first elastomeric layer is then formed on the fabricated FPD by encapsulating all the desired mold features. The first elastomeric layer is then joined onto a support substrate layer to allow for easier processing in the subsequent steps. Concurrently, a second elastomeric layer is formed using the same process described above, with the exception of the second layer not being bound to a support substrate. After formation of the two elastomeric layers, alignment and subsequent binding of the layers follow to produce a single monolithic elastomeric structure. Fabrication of the Nanoflex valve onto the device formed the foundation of Fluidigm's Integrated Fluidic Circuits (IFCs), which are used across a variety of genomics and proteomics applications [5,7].

Nanoflex™ valve

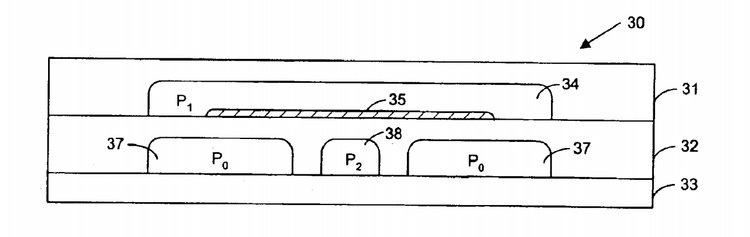

The Nanoflex™ valve has a simple rubber membrane that deflects under pressure to pinch off flow fluids in the microchannel. The valve is made from two distinct layers of elastomeric rubber formed in a micro-patterned mold. The rubber layers deflect precisely at the intersection of the channels in the bottom layer, creating a valve when pressurized liquid flows through the channels in one layer of the chip. Figure 3 shows the first embodiment of the micro-fabricated pressure amplifier system that employs the mechanism of the Nanoflex valve in the IFC. The system works by placing a fluid at pressure P1 in chamber 34. When pressure P1 increases above pressure P0 and P2 in chambers 37 and 38 respectively, a force is applied on the rigid layer 35 causing it to push against the movable walls of chambers 37 and 38, reducing its cross-sectional area and restricting flow in the bottom layer 38 which allows the flow of reagent solutions [8].

Products

As of 2020, Fluidigm has eight instruments that they currently offer to customers. Their products have been used in a variety of research disciplines such as Immune profiling, Immuno-Oncology and Agricultural – Genomics,

Microfluidic IFCs

Fluidigm's products are based on microfluidic technology, their Integrated Fluidic Circuits (IFCs) play a major role in their portfolio of biological research equipment and its basic mechanisms have been described above. One such example of their consumables is the Dynamic ArrayTM IFC which is used in the BioMark HD machine to perform qPCR (quantitative polymerase chain reaction), which is a process that uses fluorescence to measure real-time information about reaction rates on the production of relative and absolute amounts of DNA.

Preparation of reagents for this IFC occurs by manually loading samples onto the right side wells and pairs of primers on to the left side wells. After the IFC has been prepped, the chip is then loaded onto a controller that distributes the fluids all throughout the IFC, after the controller the IFC is then loaded onto the BioMark HD system to perform qPCR [3]. Several advantages have been associated with IFCs that help it lead in liquid-handling applications in a cost-effective way. Firstly, the small size of the Nanoflex™ valves present in the IFCs help accommodate a plethora of reaction chambers, channels, etc. Secondly, the dispensing of reagents and solutions occur with a high reproducibility rate due to the geometry of the chambers. Thirdly, the elastomer being used makes these IFCs gas permeable, therefore, microscopic gas bubbles do not get trapped in channels and harm results. Finally, IFCs allow researchers to run assays with their designed reagents, as well as, pre-optimized reagents from Fluidigm itself, owing to its versatility. Using the IFC model, Fluidigm has been able to develop a multitude of microfluidic devices for their corresponding instruments which are used by various disciplines in the life-sciences field.

IFC controller

The IFC Controller module controls the pressure to precisely meter fluids into the respective fluid channels on the IFC device using a single bay. The controller module is pneumatically operated using a desktop computer. The module is designed to have a built-in air compressor capable of maintaining pressures between 50-80 psi. The PC present inside the controller module regulates and monitors the performance of the instrument. It consists of a single loading bay station to hold the IFC, which is shuttled in and out of the module using a pneumatic cylinder, a barcode reader is also present to scan the IFC once shuttled into the module. All user-specific functions can be carried out using the touch screen. The module activates pneumatic cylinders through a set of solenoid valves and regulators. Ejection of the IFC cassette from the module causes the shuttle solenoid valve to move to is ejected position. Similarly, the shuttle moves the IFC cassette into the module once the Load option is chosen. Once loaded, the IFC comes into contact with the removable interface plate to form a seal. Air pressure is then directed through the interface plate into the IFC, allowing pressurization of fluids and control channels.

Applications of Products

Microfluidic Metagenomics

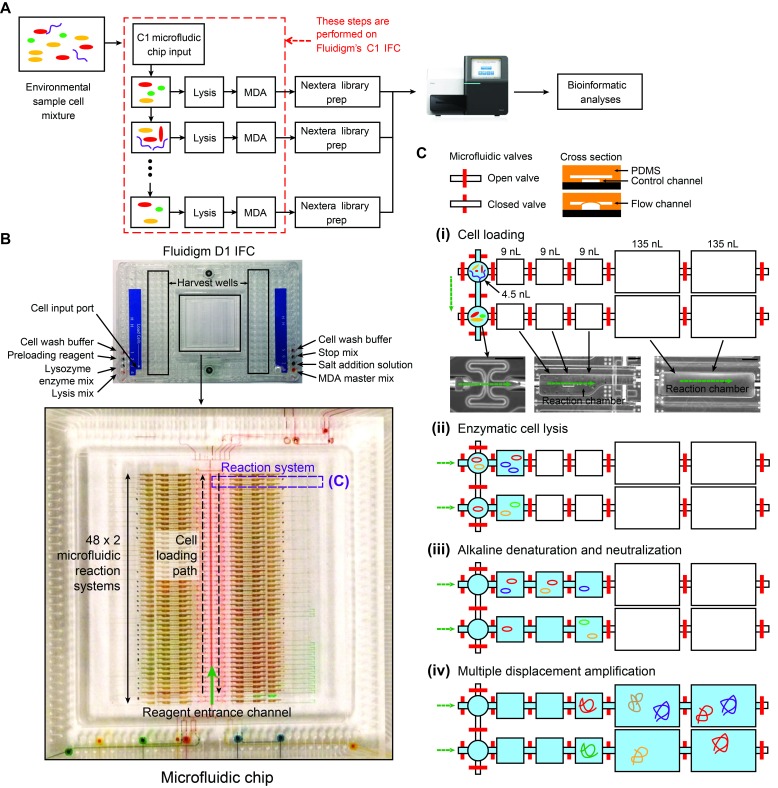

Metagenomics is the study of genetic material which is recovered directly from environmental samples. Traditional genome sequencing procedures such as shotgun metagenomics sequencing allow for the assembly of genomes from a single heterogeneous sample but is limited by its complexity. Microfluidic parallelization was then implemented onto a Fluidigm IFC for its C1 module, doing so allowed the environmental sample to be divided into several small sub-samples containing about 5-10 cells. This, in turn, lowered the complexity of each sub-sample and allowed for high quality assembly while enabling a higher degree of throughput than typical single cell-methods [4].

References

[1] “Management.” Fluidigm, [[1]].

[2] “Fluidigm Raises $75M in Second Chance at IPO.” Xconomy, Luke Timmerman, 10 Feb. 2011, [[2]].

[3] “IFCs.” Fluidigm, [[3]].

[4] Yu, Feiqiao Brian, et al. “Microfluidic-Based Mini-Metagenomics Enables Discovery of Novel Microbial Lineages from Complex Environmental Samples.” ELife, ELife Sciences Publications, Ltd, 5 July 2017, [[4]].

[5] Unger, M. A., and S. R. Quake. “Monolithic Microfabricated Valves and Pumps by Multilayer Soft Lithography.” Science, vol. 288, no. 5463, July 2000, pp. 113–116., [[5]].

[6] Spurgeon, Sandra L., et al. “High Throughput Gene Expression Measurement with Real Time PCR in a Microfluidic Dynamic Array.” PLoS ONE, vol. 3, no. 2, 2008, [[6]].

[7] David S. Cohen. Method and system for manufacturing integrated fluidic chips. United States Patent US9579830B2. 23rd July 2007

[8] David N. Fernandes et al. MICROFABRICATED FLUIDIC CIRCUIT ELEMENTS AND APPLICATIONS United States Patent US6953058 B2. 11th October 2005