Applications of 3D Printing

Tissue Engineering

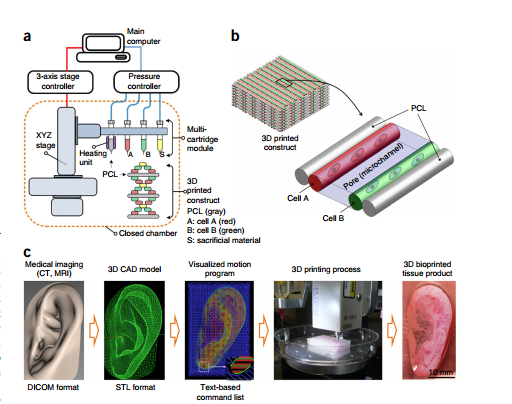

Let's say Mike Tyson bit off more then just a chunk of your ear. 3D bioprinting has the potential to customize a new ear for you. Bioprinting is a 3D printing technique which allows for tissue-like structures to be created using biomaterials which could be cells or growth factors. Bioink is the material used to create the desired structure, and the structures are created layer by layer just as in other methods of 3D printing. The difference with this is live cell suspension is used rather than a thermoplastic or PDMS. This means bioink is composed of living cells along with a compatible base which allows the cells to grow and have nutrients. The amount of bioink deposited for each layer depends on the type of tissue that is being printed along with the number of nozzles. As the layers are added, the layer starts to solidify which is defined as crosslinking. This type of 3D printing is used to imitate natural tissues, so it is most often in bioengineering and medical needs. It has also recently been used in reconstruction and regeneration of cartilage tissue. In general, this method is extremely important when it comes to mimicking the environments of micro and macro tissues and organs which is used in clinical trials along with drug testing. In the future, this could be use to create artificial organs used as organ transplants or for tissue repair; bioink allows for the product to be patient-specific since their cells are being used which is why this method is so promising for tissue repair and organ transplants. [2]

Soft Robotics

Soft robotics is a relatively new development in the field of robotics in which robots are developed with soft, flexible materials in contrast to the rigid materials used in conventional robots. Many robot structures, whether rigid or soft, are inspired by nature, mimicking humans, spiders, and several other animals. Robots with rigid bodies are typically designed to perform a single task efficiently, but it is difficult for rigid robots to adapt to changes in their environment. In addition, the hard surfaces and rigid joints of rigid robots render them unsafe for human interaction. [3] In contrast, soft robots are able to adapt to their environment and pose much less of a physical threat to humans. In this field, 3D printed microfluidic robots are a recent advancement that combines microfluidic technology and soft robots to create fully soft, autonomous robots. [3]

Robots made using soft materials are resilient and are able to adapt to different environments. However, many robots encased in soft materials still rely on control systems composed of hard materials. Creating fully autonomous robots with flexible analogues of these rigid control systems has posed a great challenge. One such example of an untethered robot composed of only soft materials is the Octobot, developed at Harvard University.[4]

Food Science

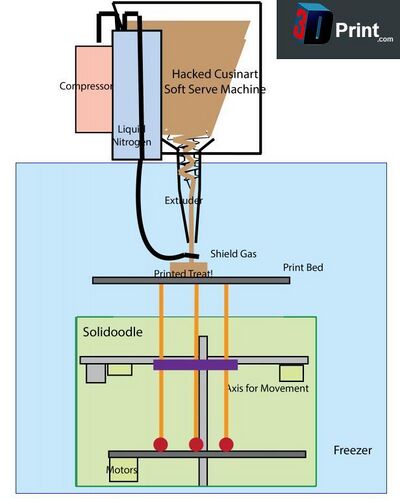

As the global population size increasing with time, providing sustainable nutrition and appealing food becomes an ongoing problem. [5] Since 3D printing technique can create desired and appealing 3D objects using various materials, this technique can serve as a new potential cooking way to feed all the global population. For example, insects are highly nutritional, they are rich in proteins and healthy fats, but most people do not accept eating insects. Utilizing this 3D printing technique, more food materials can be used and provided to the public. The appearance and texture of food product can be improved, more people can accept healthy but unappealing food. Food can be personalized by adding or reducing certain ingredients in the food "ink" for special treatment or extra care.

Fused Deposition Modeling (FDM) method is normally used for 3D printing food. Molten materials in liquid state, such as sugar, chocolate, gelatin can be printed using this method; Purees, gels, and doughs can be deposited directly without any structuring agent to support the structure. The fundamental structure of a 3D food printer usually has an extruder which is a syringe that is connected to an electric engine at one end and few nozzles at the other end. Ingredients are mixed and stored in reservoirs and containers, the nozzles deliver the ingredients, extruders are used to push different materials or color mixing by a colormix generator. Materials are layered and deposited onto he heating platform, the platform can be also used to cook the row food. [5]

Bioprinting

Bioprinting is a 3D printing technique which allows for tissue-like structures to be created using biomaterials which could be cells or growth factors. Bioink is the material used to create the desired structure, and the structures are created layer by layer just as in other methods of 3D printing. The difference with this is live cell suspension is used rather than a thermoplastic or PDMS. This means bioink is composed of living cells along with a compatible base which allows the cells to grow and have nutrients. The amount of bioink deposited for each layer depends on the type of tissue that is being printed along with the number of nozzles. As the layers are added, the layer starts to solidify which is defined as crosslinking. This type of 3D printing is used to imitate natural tissues, so it is most often in bioengineering and medical needs. It has also recently been used in reconstruction and regeneration of cartilage tissue. In general, this method is extremely important when it comes to mimicking the environments of micro and macro tissues and organs which is used in clinical trials along with drug testing. In the future, this could be use to create artificial organs used as organ transplants or for tissue repair; bioink allows for the product to be patient-specific since their cells are being used which is why this method is so promising for tissue repair and organ transplants. [2]

References

- ↑ Kang, HW., Lee, S., Ko, I. et al. A 3D bioprinting system to produce human-scale tissue constructs with structural integrity. Nat Biotechnol 34, 312–319 (2016). DOI: https://doi.org/10.1038/nbt.3413

- ↑ 2.0 2.1 Atala A, Murphy S. 3D bioprinting of tissues and organs. Nature Biotechnology 2014; 773-785. DOI: https://doi.org/10.1038/nbt.2958

- ↑ 3.0 3.1 Daniela R, Michael T. Design, fabrication and control of soft robots. Nature 521, 467–475 (2015). DOI:https://doi.org/10.1038/nature14543

- ↑ Michael W, Ryan T, Daniel F, Bobak M, George W, Jennifer L, Robert W. An integrated design and fabrication strategy for entirely soft, autonomous robots. Nature 536, 451–455 (2016). DOI:https://doi.org/10.1038/nature19100

- ↑ 5.0 5.1 Yang F, Zhang M, Bhandari B. Recent development in 3D food printing. Crit Rev Food Sci Nutr 2017;57:3145–53. DOI:10.1080/10408398.2015.1094732

- ↑ Clare S. Barilla Continues to Develop Pasta 3D Printer, Envisions Gourmet Customization, 2016. 3DPrint.com. [[1]]

- ↑ 3DPrint.com. I Scream, You Scream, We All Scream for 3D Printed Ice Cream? 3D Ice Cream Printer is Created at MIT, 2014. 3DPrint.com. [[2]]