3D printing - Luke Ruksnaitis, Lilin Zhao, Rune Percy

Overview of 3D printing

Overview of 3D printing

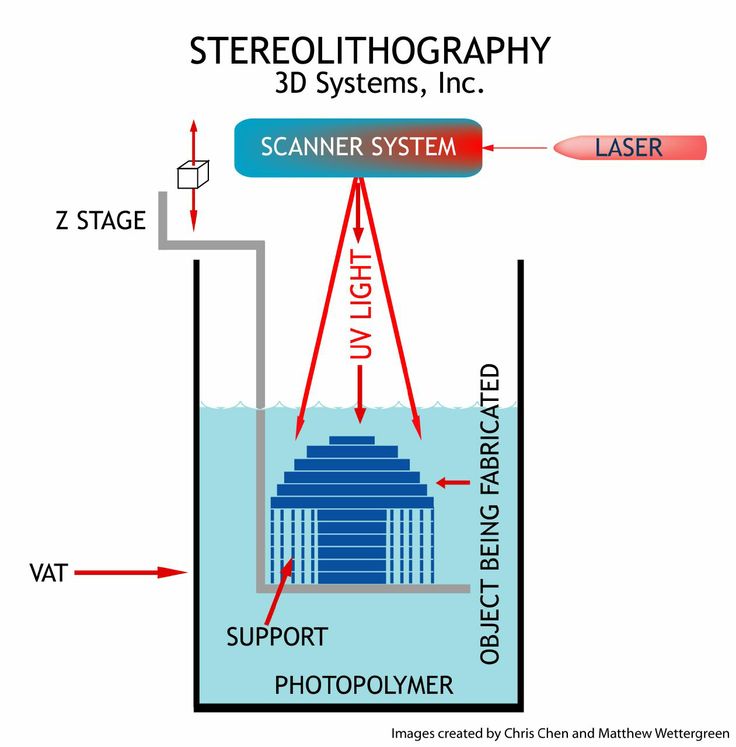

Rapid prototyping and additive manufacturing are the fancy descriptive terms for the technology commonly known as 3D printing. This is a technology where crude materials are processed by a computer controlled machine to create and form objects and functioning devices from the instructions given by the computer aided design. 2D printing which was developed in the 15th century changed the world as far as being a catalyst for the education of society and the higher minded development of the world population. The development of 3D printing is now in this century having a revolutionary impact on science and education. 3D printing was first developed and described in 1986 when Charles W. Hull invented a stereolithography 3D printing method where thin layers of material cured by ultra violet light were printed in layers to form a 3D structure. 3D aims to bring the words off of the page and bring society to a higher developed level by allowing advanced technologies to easily be developed such as microfluidic devices. "Typical materials used in rapid prototyping are types of plastic, which can be extruded through a nozzle into various shapes. By controlling the rate of flow and repositioning the nozzle, the computer can create virtually any shape. Objects are built in thin printed layers forming a horizontal cross-section of the eventual object. After the plastic hardens, the newly created object can be removed and used for its intended purpose." (Lee Lerner). 3D printing is analogous to printing out a computer generated documented such as an essay with a standard printer. The essay is the blueprint, and the printer automatically prints everydetail of this blue print. A 3D printer takes a 3D blue print of something and prints it with more materials then just black or colored ink in one layer on a page.

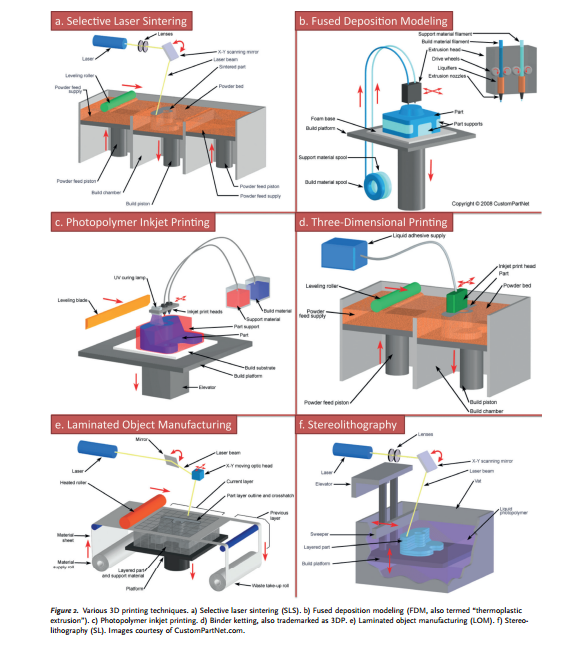

3D printing is a crucial tool for the developers of microfluidic devices. Not all 3D printing techniques are used by microfluidic developers. "the term “3D printing”—considered to be synonymous with “solid freeform fabrication”—refers to a family of additive-based manufacturing techniques. Importantly, not all 3D printing techniques are suitable for microfluidics. The most widely used 3D printing techniques with relevance to microfluidics are selective laser sintering" (Au, Anthony K, Wilson Huynh, Lisa F. Horowitz, and Albert Folch). The different methods of 3D printing in microfluidics include Fabrication by Stereolithography, Fabrication by Selective Laser Sintering, Fabrication by photo polymer inkjet printing, fabrication by fused deposition modeling, and fabrication by laminated object manufacturing. These different methods of 3D printing have different levels of resolution and automation.

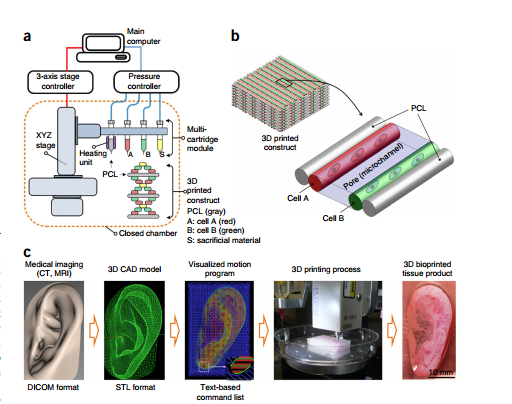

Lets say Mike Tyson bit off more then just a chunk of your ear. 3D bioprinting has the potential to customize a new ear for you.

Au, Anthony K, Wilson Huynh, Lisa F. Horowitz, and Albert Folch. "3d-printed Microfluidics." Angewandte Chemie International Edition. 55.12 (2016): 3862-3881. Print

Hausman, Kalani K, and Richard Horne. 3d Printing for Dummies. , 2014. Internet resource.

Kang, HW, SJ Lee, IK Ko, C Kengla, JJ Yoo, and A Atala. "A 3d Bioprinting System to Produce Human-Scale Tissue Constructs with Structural Integrity." Nature Biotechnology. 34.3 (2016): 312-9. Print.

Lee Lerner, K. "3D Printing." The Gale Encyclopedia of Science, edited by K. Lee Lerner and Brenda Wilmoth Lerner, 5th ed., vol. 8, Gale, 2014, p. 4383. Gale Virtual Reference Library, silk.library.umass.edu/login?url=http://go.galegroup.com/ps/i.do?p=GVRL&sw=w&u=mlin_w_umassamh&v=2.1&it=r&id=GALE%7CCX3727802429&asid=0eb5397745510438593a6c6b6c9698a1. Accessed 16 Feb. 2017.

Murphy, Sean V., and Anthony Atala. "3D Bioprinting of Tissues and Organs." Nature Biotechnology 32.8 (2014): 773-85. Web.

Applications of 3D printing in Microfluidics

How does 3D printing play an important role in the fabrication of microfluidics devices? There are some key functions of microfluidic device that includes separation of liquids and samples detection and fluid manipulation. By using 3D printing the time needed for the fabrication process is greatly reduced and it can be done with just one machine and fully automated which allows the process to be easily replicated. The 3D printing offers the opportunity to fabricate the whole microfluidic device in a single step without the need of the assembly step. Stereolithography (SLA) was the first commercialized 3D printing machine. Thermoplastics photopolymers are used as the base material for SLA fabrication. The photopolymer is in a liquid state before fabrication. A UV laser was used to scan the material and hardened by using low powered, highly focused laser. The platform is lowered by a distance equal to layer thickness (usually 0.05-0.15mm) and then the laser moves on to the subsequent layer and repeat the process again until the desired product is finished. The excess polymer in each layer stays in liquid state and rinsed off the platform. A major advantage of SLA fabrication is the very high precision of the surface resolution.

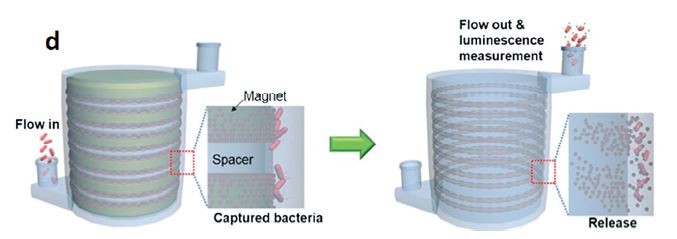

A good example of a microfluidic device created by the SLA is the immunomagnetic flow assay on-a-chip designed by Lee and team [1]. This experiment is a great example of how works that were previously restricted to laboratory due to their size can now be studied with the aid of 3D printing. The commercialized 3D Viper SLA system printed a cylindrical 3D micro-channel named as a High Capacity Efficient Magnetic O-shaped Separator(HEMOS). (Figure 1)

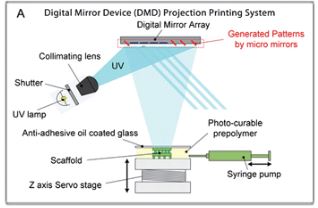

Digital Micromirror Device-based Projection Printing (DMD-PP) is another type of 3D printing technology. It is a projection system that uses a controllable digital mirror to reflect laser light in an entire plane which then allows the curing of an entire layer at a time. (Figure 2) Compared to SLA system the DMD-PP the building structure is bottom-up different from the SLA which requires the stage to move as well as the laser. An example of microfluidic device created using the DMD-PP is the 3D in vitro microchip which is made of hydrogel with a honeycomb structure which allows the microchip to mimic the 3D vascular morphology of an in vivo micro environment.

References

W. Lee, D. Kwon, B. Chung, G. Y. Jung, A. Au, A. Folch and S. Jeon, Anal. Chem., 2014, 86, 6683–6688.

Soft Matter, 2012, 8, 4946 DOI: 10.1039/C2SM07354D

Lab Chip, 2015, 15, 3627 DOI: 10.1039/C5LC00685F

R. Liska, M. Schuster, R. Inführ, C. Turecek, C. Fritscher, B.Seidl, V. Schmidt, L. Kuna, A. Haase and F. Varga, J. Coat.Technol. Res., 2007, 4, 505–510.

C. W. Hull, Journal, 1986.