User:Andy Maloney/Notebook/Lab Notebook of Andy Maloney/2010/06/17/Temperature stabilization

Objective heater

Update Andy Maloney 10:16, 26 January 2011 (EST): For a different description with data and references, please visit my Instructables page describing this build.

I have finally finished my objective heater build and tested it to some degree. The only issue I have with the setup right now is that measuring temperature and having the computer log it is somewhat of a problem still. Other than that, the system works spectacularly and is relatively cheap. It's actually a lot cheaper than the commercially available units and it was fun to build.

Materials

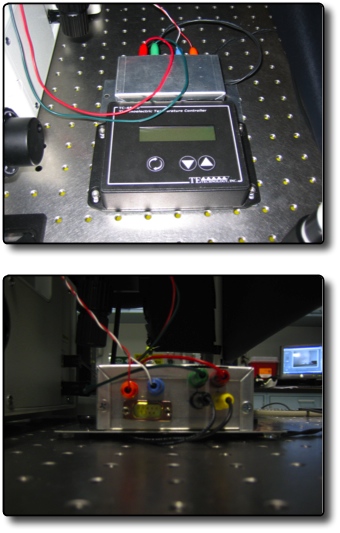

- Temperature controller.

- I should note that TeTech has an OEM version of this controller that I must admit I like better than the one that has the LCD readout. Mainly because the program is much more intuitive to control than the LCD push button readout. But, both work spectacularly and it is nice to be able to read off the temperature of the controller easily.

- Objective thermal spacer.

- This is just a piece of ABS with the right RMS threads on it. It's remarkably expensive but I supposed it is worth it since finding the RMS die is rather difficult for some reason. You can get a tap pretty easily from Thorlabs though.

- Power supply.

- I have never had problems with MeanWell power supplies.

- Box and Box cover.

- This is to safely house your power supply so that you don't shock yourself.

- LEDs.

- These are to indicate when the power is on.

- Switches.

- To turn on the power supply.

- Flexible heaters.

- I really like this stuff. Resistive heaters that you can cut out and use almost anywhere.

- Copper tape.

- You don't have to use this type of tape as it is somewhat pricey. It's what I had available but you can also use aluminum tape. Of course you won't get the same NASA space looking affect on your objective with aluminum as opposed to copper.

Build

The temperature controller comes with a thermistor of which, I put banana connectors on the ends of the wire. The reason I did this is because I didn't feel it was appropriate to have exposed wires/terminals on the temperature controller. Mainly because there is a possibility to have high current going through them. So, I built a small box as a cover. This turned out to be a tremendous nuisance and another reason why I think using the OEM temperature controller was probably a better choice. But again, I'm conflicted since I like the LCD readout a lot.

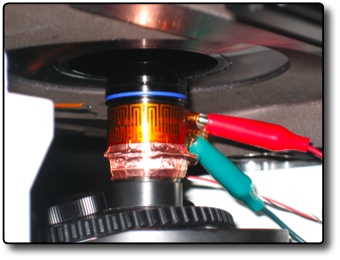

I just taped the thermistor at the base of the objective. This required some tape massaging in order to get it to stick properly using the copper tape.

Once the thermistor is on the objective, you can put the flexible heating element on it. Thankfully the stuff from Omega has a sticky back to it so just peel and stick it on the objective. I've been using for about a week now and have had no problems with it. As you can see in the picture, There are 2 alligator clips attached to the heating element. I had to do this since I couldn't for the life of me solder anything to the leads. Those wires run to the temperature controller and connect to it via banana connectors.

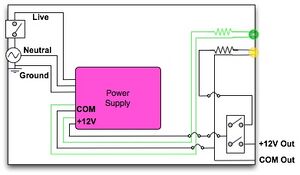

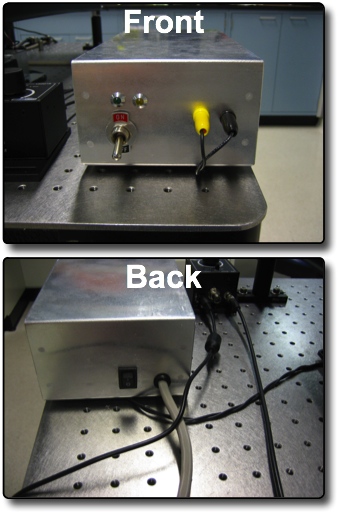

The power supply is housed in the aluminum box. I'm not going to go through the complete build for it. Suffice it to say, if you don't know what you are doing in the area, be careful or let an expert do it since you will be working with power from the wall. The circuit diagram for it is below.

The important thing about the box is to make sure you connect the box to earth ground. Also, you should put a fuse in it just as a safety precaution to protect the power supply. I chose to have a main switch to power the power supply (green indicator LED) and another DPST switch on the front to turn on the +12VDC output to the temperature controller. This may be overkill but I got to use 2 LEDs with this setup. The green one shows the unit power on and the yellow one shows power to the temperature controller.

If I could have found a bigger switch on the front, then I would have put that one in. Why? Because everybody loves switches.

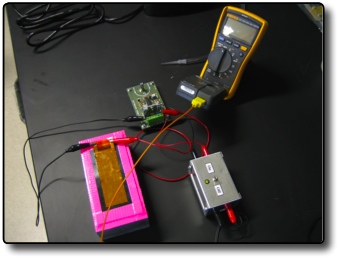

Right now I have another K type thermometer hooked up to the objective to measure the temperature via a NI USB 6009 and a Fluke 80TK meter. This is a terrible setup and I am thinking about switching to a PT100 as the measurement device.

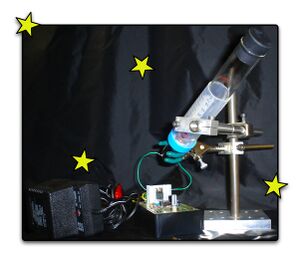

Slide warmer

I used another piece of the flexible heating elements to make a slide warmer. This one is really basic. It uses a DC motor speed controller that uses pulse width modulation to control the DC motor speed as the current controller for the heating element. I mounted it on a giant piece of aluminum and hooked it up to the motor controller. The motor controller is then supplied 20VDC @ 500mA through an AC/DC wall converter. After some finesse with the potentiometer, you can stabilize the temperature of the slide being warmed to ±0.1˚C which is good enough.

Some that have read my notebook will notice that the DC motor controller and the switch were components used in both my Spin Master Micro (my $30 version of a Rotovap)

and my Spin Coater 3000 (my $40 version of a microscope slip spin coater)

<html> <object width="425" height="344"><param name="movie" value="http://www.youtube.com/v/C3oXdlWQg5I&hl=en&fs=1&"></param><param name="allowFullScreen" value="true"></param><param name="allowscriptaccess" value="always"></param><embed src="http://www.youtube.com/v/C3oXdlWQg5I&hl=en&fs=1&" type="application/x-shockwave-flash" allowscriptaccess="always" allowfullscreen="true" width="425" height="344"></embed></object> </html>

I guess I will call this rebirth the Slide Warmer XJ2

LED Unit

Error creating thumbnail: File with dimensions greater than 12.5 MP

As you can see, I was able to get a stable reading from a whole casein study using the temperature stabilization from TeTech. The only issue I have with this is again, I am getting this increase in speeds at the beginning of my experiments. As I found out in these (1, 2, 3) notebook entries, the slide has some thermal sinking capabilities and needs time to warm up. But, that was the whole purpose as to why I made the Slide Warmer XJ2.

Anthony suggested that there could be loss in temperature due to my transferring the slide from the warmer to the microscope and there definitely is. So, if I use the Hg lamp and have it attached to the microscope, I have to move the slide from the warmer to the microscope very quickly.

LED light source

In order to completely get rid of any heating that may be caused by the light source, I tried an LED from Thorlabs. The only problem is that I burnt out the LED from Thorlabs rather quickly and had to exchange it with a less powerful LED.

When I did this, I used my 29% rhodamine labeled microtubules and I just didn't have enough power from the light source to have the tracking program track anything.

<html> <object width="480" height="385"><param name="movie" value="http://www.youtube.com/v/gtcatkEHgrY&hl=en_US&fs=1&"></param><param name="allowFullScreen" value="true"></param><param name="allowscriptaccess" value="always"></param><embed src="http://www.youtube.com/v/gtcatkEHgrY&hl=en_US&fs=1&" type="application/x-shockwave-flash" allowscriptaccess="always" allowfullscreen="true" width="480" height="385"></embed></object> </html>

As you can see, the microtubules are very faint. So, I used 100% labeled rhodamine microtubules and they are still faint.

<html> <object width="480" height="385"><param name="movie" value="http://www.youtube.com/v/QU8XRqVdFk0&hl=en_US&fs=1&"></param><param name="allowFullScreen" value="true"></param><param name="allowscriptaccess" value="always"></param><embed src="http://www.youtube.com/v/QU8XRqVdFk0&hl=en_US&fs=1&" type="application/x-shockwave-flash" allowscriptaccess="always" allowfullscreen="true" width="480" height="385"></embed></object> </html>

Thankfully, this product is new enough that Thorlabs doesn't sell the LED individually from the aluminum mounts. I could try and replace it with Thorlabs as the technician I spoke to said they can do that. But, I'm not convinced this is beneficial since it will be 1 week to get it to them and then another week to get us the new part. So, I purchased 2 LEDs that are sold in the USA. One is on a star that I know will fit in the mount and the other is on a square that will take some figuring out how to mount properly but shouldn't be a problem.

I have two main reasons why I want to use an LED instead of the Hg lamp.

- There still exists an initial speed increase that I want to see if it will disappear when using an LED.

- LEDs are cheap and a lot safer to use/handle than the Hg lamp.

Of course there are downsides to using an LED.

- Not as bright as the Hg lamp.

- Not as bright as the Hg lamp.

- Not as bright as the Hg lamp.

This may be a big problem. But, I want to see if I can get away with using the LEDs. Worst case scenario is to keep the Hg lamp and use a liquid light guide to keep the Hg housing from the microscope. This of course will entail a lens, mounting to the Hg housing, mounting to the microscope...