Ear on a Mouse, by Brittany Forkus

The Novel Approach to Tissue Regeneration

One of the most critical moments in the field of tissue engineering occurred in the city of Boston in 1954 in a project directed by Dr. Joseph Murray. Under his control, a team of doctors successfully carried out the first solid organ transplant. In this case, a kidney was transplanted from one identical twin to his severely ill brother. This event stimulated a widespread research movement where scientists and labs began extensive work in the fields of transplantation biology, immunology, and other related disciplines. Along with this research endeavor came signifcant advancements in the development of surgical techniques and in the attempts to improve host immune suppression. However, even decades later, many challenges still remain between tissue transplants and clinical success. Some of these challenges include the associated expenses associated with actual transplant procedure, the necessary labor-intensive care, and the high possibility of host rejection. Still today, the primary problem resides in the fundamental issue of organ and donor scarcity (1).

The majority of research labs up through the 1980’s were focusing their attention on ways to combat the “immune problem” to improve organ transplantation technology and developments were being made use xenografts and biohybrid support devices. It wasn’t until the mid 1980’s when Joseph Vacanti, MD of the Children’s Hospital of Boston teamed up with Dr. Robert Langer of MIT’s polymer science department that the idea of actually engineering functional tissues for use in transplantation become a potential solution to combatt the organ scarcity problem. Together, their work would come to redefine the field of tissue engineering (1).

The "Vision"

The Concept

Vacanti and Langer envisioned the development of a system capable of generating new and natural permanent tissue replacements by using 3D synthetic biodegradable matrices seeded with parenchymal cells. Conceptually this idea held many of the answers to the current problems associated with tissue replacement. Ideally, the polymer scaffold could be designed to promote cell proliferation and differentiation, allow vascular ingrowth, be controllably degraded, and completely resorb in vivo leaving only the newly formed tissue. If successful, the development and implementation of this device could provide several advantages over traditional methods as the scaffolding could be potentially manipulated to allow increased control over the release of hormones and growth factors essential to cell functionality, the attachment to the cells to the matrix before introduction to the body could increase the number of cells capable of being implanted, the mold could be structured into various shapes, and this method could allow for autologous or allogenic transplants (1).

Preliminary Data and Supporting Evidence

In pursuit of their research endeavors, the Vacanti brothers and Langer based their work on several fundamental observations that were gathered in preliminary studies. First off, all organisms are continually experiencing the processes of renewal, remodeling, and replacement of their cells. Secondly, cells that are dissociated from their natural environment are capable of reforming structures when appropriately signaled by their surrounding environment to do so. Thirdly, organ parenchymal cells are anchorage dependent with the cell matrix and play essential roles in cell shape, division, and differentiation. Also, previous studies had demonstrated that 2-3mm3 is the largest volume of tissue that can be implanted that allows for adequate nutrition, gas exchange, etc. until angiogenesis occurs. With these biological observations in mind, the Vacanti brothers and Langer set out to design a novel 3D polymer scaffold that could be loaded with paranchymal organ cells in culture and then implanted into a host (1).

The Ideal Matrix

One of the pivotal considerations in the design of this polymer scaffold for the engineering of replacement tissues is in regards to the selection of an appropriate matrix material. This ideal scaffolding material would need to have several essential characteristics and tuning capabilities for proper functionality in this application for it must be--biocompatible, mechanically stable, flexible, controllably degradable, resorbable, and capable of making specific chemical interactions with the seeded cells. In terms of biocompatibility, it is essential that the polymer avoids eliciting an undesired immune response in the host which could ultimately result in immune rejection and procedural failure. Physically, the matrix needs to have a certain degree of mechanical stability and flexibility to ensure that it can provide the necessary support and space for tissue formation, so that it can be easily designed and constructed into variable shapes and structure, and it must be able to withstand the procedure and in vivo environment in order to maintain this structure upon implantation. Finally, some desirable tuning capabilities of the ideal polymer scaffold would entail tunable degradation characteristics, the matrix should be capable of resorbing to the body while leaving only natural, functional tissue, and the manipulation of surface chemistry to dictate desired interactions between the seeded cells and the matrix surface (1).

The Vacanti brothers and Langer determined that polymers from the group of polyesters and the families of polylactic acids, polyglycolic acids, and their copolymers were the best candidate for their scaffolding material. These polymers were not only biocompatible, stable, and flexible but they also could be degraded by hydrolysis to carbon dioxide and water products and the resorption rate of the polymer could be designed to vary from a time scale of months to years depending on the ratio of polymer monomers utilized (1).

Steps to Reality

The years following the Vacanti-Langer pairing in 1985 were characterized by rapid experiments and developments in the field of tissue engineering to elucidate the feasibility of the envisioned scaffolding device for tissue regeneration.

One of the initial experiments performed utilized a small disk of polyanhydride in which hepatocytes were seeded in a monolayer on the wafer and implanted into the animal (see Figure 3). Analysis revealed that the cell number and density were not sufficient for successful engraftment (1). However, this experiment led to the realization of a fundamental constraint. All cells require the adequate exchange of oxygen and nutrition with the environment and removal of waste products. Since mass transfer only occurs at the extracellular surface, it is relatively easy to achieve this for a single layer of cells. As the cell mass increases, the surface for exchange increases—as does the mass of cells requiring this exchange. Thus in the development of scaffold shapes, these considerations need to be taken into account to allow for adequate nutritional acquisition and survival (2). As Joseph Vacanti so eloquently described this problem, “…you might as well try to grow a houseplant inside a basketball (3).” In pursuit of an answer to this fundamental issue, Vacanti claims the idea came to him when he was observing seaweed on the Cape Cod shore during a family vacation. Under the skin of the seaweed lies a branching network of hollow branches that meet the surface volume to area requirements and provide fresh oxygen to the organism while discarding waste byproducts. This seaweed design of a branched network inspired the use of much more airy, "cotton-ball like" polymers in future experiments (2).

Several years later, in 1991, another major experimental breakthrough occurred under the leadership of Dr. Charles Vacanti at the University of Massachusetts Medical School (1). The group was able to successful develop homogeneous plates of cartilage each weighing up to 100mg by using synthetic biodegradable templates loaded with chondrocytes. These scaffolds were then implanted under the skin of athymic mice and analyzed. The newly formed cartilage maintained the relative shape and dimensions of the original templates upon resorption of the polymer. Additionally, lacunae were observed in specimens harvested at 81 days and not in those harvested at 49 days or earlier. These findings suggest that the tissue matured from metal to adult cartilage. In further support of this conclusion type III collagen, which is characteristic of immature mammalian hyaline cartilage was observed in the younger samples, while Type II collagen, which is characteristic of mature mammalian cartilage, was observed in specimens implanted for greater than 49 days (1).

The next practical step en route to developing the envisioned scaffold entailed the engineering of cartilage in specific predetermined shapes and shapes. This was performed by Puelacher et al. in 1993 when they developed models of human nasal cartilage using nonwoven PGA mesh which were bonded with a 5% solution of polylactic acid. These polymer forms were seeded with a suspension of chrondrocytes obtained from newborn bovine hyaline cartilage. These contructs were then implanted in athymic mice for 8 weeks. Analysis revealed that the size and shape of the implants was maintained upon polymer resorbtion leaving a relatively resilient tissue behind that was capable of restoring its original confirmation after bending (1).

The Classic Mouse Experiment

The Objective

Total ear reconstruction is a very challenging issue for plastic surgeons due to the complex structure of the ear and the tissue has a limited ability to regenerate (2). However, there would be serious clinical benefits to having an improved regeneration method for infants are born daily with underdeveloped ears and others lose these organs in traumatic experiences (1). Currently there are two major alternatives for total external ear reconstruction: alloplastic implants and autogenous cartilage grafts. Alloplastic implants are typically made of silicone or polypropylene into premade forms. One advantage to this method is the materials are available in a relatively limitless supply and no additional labor or time is needed to shape the device as they come preformed. However, these materials are highly susceptible to infection and don’t exhibit consist long-term durability. On the other hand, the use of autogenous tissues has better long term durability, but there is a trade off for a lot of time is required to shape the scaffold and there is often an insufficient supply of usable cartilage (4).

In the 1990’s Vacanti and Langer successfully grew an ear on the back of an athymic mice which they nicknamed Auriculosaurus (3) (see Figure_).

The Science Behind it

Construction of the Device

In order to construct the actual shape and dimensions of the scaffolding device, the ear of a 3-year old child was cast using alginate as the impression material. A cast of plaster was then created from the alginate impression and used as a mold for the design of the synthetic biodegradable polymer constructs. The polymer used was composed of polyglycolyic acid fibers in a nonwoven mesh that was approximately 100um thick with a diameter of roughly 15um. The mesh fibers were then bonded to upon immersion in 1% solution of polylactic acid for 2 seconds. After this process, the polymer was shaped into the form of the ear using the plaster mold and the devices were placed in 35-mm polystyrene tissue culture dishes (4).

Isolation of Chondrocytes

According to Cao et al., the chondrocytes were obtained from “freshly slaughtered” calf forelimbs upon receipt from the local slaughterhouse. The cells were removed from the articular surfaces of joints and subjected to collagenase digestion, centrifugation, filtration, and various buffering conditions in preparation for the seeding process (4).

Loading the Polymer and Implantation into Athymic Mice

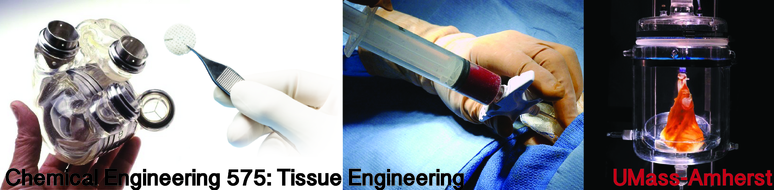

In order to seed the polymers with the dissociated bovine cells, 3mL aliquots of the chondrocyte suspension consisting of 1.5x10^8 cells placed on the polymers and allowed to incubate for 4 hrs at 37 degrees Celsius to promote attachment to the fibers (see Figure_). Culture medium was enhanced with 10% fetal cald serum, 5 ug/mL ascorbic acid, 292 ug/mL L-glutamine, 100 U/mL penicillin, and 100 ug/mL streptomycin. The matrices were incubated at 37 degrees Celsius in 5% CO2 for 1 week and culture medium was replaced every 48 hours (paper). Scanning electron microscope images show the attachment of the chrondrocytes to the matrix prior to incubation and also show the presence of extracellular matric components being secreted by the cells which confirms their respective ability to perform differentiated functions. Following incubation, the devices were subcutaneously implanted into the athymic male mice of 4-6 weeks old using sterile surgical procedures and general anesthesia (4).

Results

Although the experimental set-up of this procedure was conceptually simplistic, the results yielded invaluable insight into the idea of engineering tissue for regeneration by mean of 3D scaffolds. Following 6 weeks of in vivo incubation, the control group exhibited no trace of cartilage formation. Upon removal of the stent, the skin of the mice retained its original appearance and the polymer was resorbed as expected. However, the most significant results were in regards to the differences observed in experimental groups I and II. Following 3-4 weeks of in vivo incubation, differences in the shape of the ear became apparent. Specimens from experimental group I has a morphology almost identical to that of the implant that was well-established after 4 weeks and it was maintained for the additional 8 weeks following stent removal (see Figure _). In contrast, the mice of experimental group II developed an ear that only roughly matched that of the polymer scaffold as it was reduced in size and distoreted in shape as is apparent in Figure _ (4).

The Social Response

Although to the scientific community and the pioneers of tissue engineering, this breakthrough was monumental and exiting opening numerous avenues for investigation and raising valuable scientific questions, it had an equally strong response on the scientific community. Following the publication of Vacanti’s paper in August 1997, a strong oppositional outrage was expressed by the anti-genetics group and animal rights activists. This disfavorable social response was facilitated by a film made by BBC’s Tomorrow’s World, as well as, an ad that was depicted in the New York Times by the group called the Turning Point Project (see Figure 6).

The ad showcased the image of Vacanti’s mouse with a misleading captain that stated, “This is an actual photo of a genetically engineered mouse with a human ear on its back.” This statement implied that the scientists had altered the mouse’s genome by inserting segments of human DNA. The strong response that was elicited by the social groups still persists today and some of the classic captions from the article are listed below to help foster a better understanding of how the social community was perceiving these scientific advancements (5):

“Does anyone think that it’s shocking, therefore, that this infant biotechnology industry feels it’s okay to capture the evolutionary process and to reshape the life on earth to suit its balance sheets?”

So far, there exist no half-human, half-animal “chimeras” (like mermaids or centaurs) but we may soon have them”

“Biotech companies are blithely removing components of human beings (and other creatures) and treating us all like auto parts at a swap meet.”

“Someday when one of these companies finally decides the public mood is receptive, will they make a human-gorilla combo to take care of heavy labor?”

“Have we lost our sanity”? (5)

References

(1) Atala, Anthony, and David J. Mooney. Synthetic Biodegradable Polymer Scaffolds. Boston: Birkhäuser, 1997. Print.

(2) Vacanti, Joseph. "Tissue Engineering and Regenerative Medicine." Lecture. The Jayne Lecture. Amphilsoc. Web.

(3)D'Agnese, Joseph. "Brothers with Heart." Discover July 2001. Discover Magazine. 1 July 2001. Web.

(4)Cao, Yilin, Joseph P. Vacanti, Keith T. Paige, Joseph Upton, and Charles A. Vacanti. "Transplantation of Chondrocytes Utilizing a Polymer-Cell Construct to Produce Tissue-Engineered Cartilage in the Shape of a Human Ear." Plastic and Reconstructive Surgery 100.2 (1997): 297-302. Print.

(5)Rouse, Roger. "Who Plays God in the 21st Century?" New York Times [New York] 25 May 2001, 9th ed., sec. 62. Print.