User:Andrew K Farag/Notebook/CHEM-582/2015/03/18: Difference between revisions

From OpenWetWare

(Autocreate 2015/03/18 Entry for User:Andrew_K_Farag/Notebook/CHEM-582) |

|||

| Line 6: | Line 6: | ||

| colspan="2"| | | colspan="2"| | ||

<!-- ##### DO NOT edit above this line unless you know what you are doing. ##### --> | <!-- ##### DO NOT edit above this line unless you know what you are doing. ##### --> | ||

== | ==Objectives== | ||

* | *Make films with JA230 | ||

*Make new epoxy nails experiment for adhesive strength | |||

*Repeat thermal conductivity test for epoxy only film | |||

*Create new agar plates | |||

*Growing cells on films in the dark | |||

**use 200 microliter this time, instead of 600 microliter. | |||

==Thermal Energy== | |||

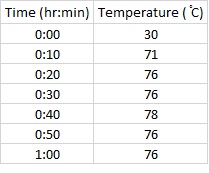

#The experiment was set up on the bench instead of the hood to prevent airflow | |||

#A large tray was set up next to the hotplate to stop air flow from the window | |||

#30 ml of water was measured out to make sure each experiment was consistent and prevent boil over | |||

#The experiment was measured every ten minutes for one hour | |||

#After the test was completed the dish with epoxy coating was allowed to cool and dry. The epoxy was removed for the dish and cut in half, thickness was measured using a caliper in the middle of each half and averaged. The epoxy coating thickness was mm | |||

[[Image:epoxytest2.jpg]] | |||

*Table 1. Shows the duplicated results for pan coated in epoxy only for the thermal conductivity test. | |||

===Preparation of epoxy films with JA-230=== | |||

New films were prepared containing an alternative amine | |||

#Epoxy/10 % TiO<sub>2</sub> film | |||

#* 0.86671 g of TiO<sub>2</sub> were weighed out | |||

#* 2.14498 g of JA-230 | |||

#* 6.58167 g of epoxy | |||

#Epoxy film | |||

#* 2.16062 g of JA-230 were weighed out | |||

#* 6.64996 g of epoxy | |||

The samples were stirred using an electromagnetic stirrer, then put on a hot plate at 60°C to store for a further 15 min and then poured into an aluminum dish to sit overnight before curing. | |||

===Preparation of new samples for adhesive strength test=== | |||

A new adhesive test is to be carried out using zinc ring nails. Because of previous variations with amount of weight required to detach the nails from the metal plate, more trials will be done per epoxy type. | |||

* For Friday's experiment 4 nails cured with epoxy alone will be tested. A further two nails are to be cured together and tested using PASCO materials testing. | |||

The epoxy mixture used to glue the nails contained epoxy and JA-400 in the following quantities: | |||

* 3.03317 g of JA-230-400 | |||

* 5.77076 g of epoxy | |||

Same procedure as with films was followed to mix the chemicals. (Stirred in electromagnetic stirrer, placed on hot plate at 60°C for 15 min) | |||

<!-- ##### DO NOT edit below this line unless you know what you are doing. ##### --> | <!-- ##### DO NOT edit below this line unless you know what you are doing. ##### --> | ||

| Line 14: | Line 49: | ||

__NOTOC__ | __NOTOC__ | ||

Revision as of 07:18, 25 March 2015

| <html><img src="/images/9/94/Report.png" border="0" /></html> Main project page <html><img src="/images/c/c3/Resultset_previous.png" border="0" /></html>Previous entry<html> </html>Next entry<html><img src="/images/5/5c/Resultset_next.png" border="0" /></html> | |

Objectives

Thermal Energy

Preparation of epoxy films with JA-230New films were prepared containing an alternative amine

The samples were stirred using an electromagnetic stirrer, then put on a hot plate at 60°C to store for a further 15 min and then poured into an aluminum dish to sit overnight before curing. Preparation of new samples for adhesive strength testA new adhesive test is to be carried out using zinc ring nails. Because of previous variations with amount of weight required to detach the nails from the metal plate, more trials will be done per epoxy type.

The epoxy mixture used to glue the nails contained epoxy and JA-400 in the following quantities:

Same procedure as with films was followed to mix the chemicals. (Stirred in electromagnetic stirrer, placed on hot plate at 60°C for 15 min)

| |