BME494s2013 Project Team1: Difference between revisions

| (32 intermediate revisions by 4 users not shown) | |||

| Line 34: | Line 34: | ||

Escherichia coli, commonly referred to as E. coli, has many different strains. The most commonly known serotypes of these bacteria can cause serious food poisoning or even fatality in humans. However, most strains are completely harmless. These strains are usually found in the gut of the host and help by producing K2 and helping with digestion. The presence of these bacteria is very beneficial for it helps to prevent pathogenic bacteria from being present in the intestine.<cite>e-coli-wiki</cite> | Escherichia coli, commonly referred to as E. coli, has many different strains. The most commonly known serotypes of these bacteria can cause serious food poisoning or even fatality in humans. However, most strains are completely harmless. These strains are usually found in the gut of the host and help by producing K2 and helping with digestion. The presence of these bacteria is very beneficial for it helps to prevent pathogenic bacteria from being present in the intestine.<cite>e-coli-wiki</cite> | ||

The Lac switch that we have created in the genetic coding of E. coli bacteria produces a glowing blue color that initially runs off of glucose and eventually runs off of lactose. With this technology, we can create a glow stick that can be used in emergency kits that will provide light in dire situations. By using a non-harmful strain of E. coli, we can create an environmental conscious and biodegradable glow stick that will not cause harm to the surroundings. | The Lac switch that we have created in the genetic coding of E. coli bacteria produces a glowing blue color that initially runs off of glucose and eventually runs off of lactose. With this technology, we can create a glow stick that can be used in emergency kits that will provide light in dire situations. By using a non-harmful strain of E. coli, we can create an environmental conscious and biodegradable glow stick that will not cause harm to the surroundings. | ||

This model would act as a proof-of-concept in the development of the device; the BioBricks available in the Parts Registry facilitated easy construction and testing of the model but do not contain the luminescent components the group would use in the distributed device. The cyan fluorescent protein (CFP), which is used in the proof-of-concept model, would necessitate the use of ultra-violet light to observe the fluorescent output. This would not be implementable in a model geared toward commercialization. Instead, the final model would use luciferase (such as [http://partsregistry.org/wiki/index.php?title=Part:BBa_I712019 BBa_I712019] or [http://partsregistry.org/Part:BBa_J52008 BBa_J52008]), which would not require the use of external stimulants to operate. | |||

This technology will prove to be very helpful for hunters or those who are outdoors for they will not have to worry about disposing of their light source. Used like a regular glow stick, the different components of the device will remain separated and will be mixed together to produce light once a certain amount of force is applied. | This technology will prove to be very helpful for hunters or those who are outdoors for they will not have to worry about disposing of their light source. Used like a regular glow stick, the different components of the device will remain separated and will be mixed together to produce light once a certain amount of force is applied. | ||

| Line 65: | Line 65: | ||

[[Image:LacOperon.jpg|thumb|1040px||center|Basic Components of a Lac Operon <cite> | [[Image:LacOperon.jpg|thumb|1040px||center|Basic Components of a Lac Operon <cite>lac-op-wiki</cite>]] | ||

==Design: Our genetic circuit== | ==Design: Our genetic circuit== | ||

| Line 107: | Line 107: | ||

<!-- Show a network/ circuit diagram of your team's Lac switch. Include a paragraph to explain how it works (i.e., how to switch the system from on to off and vice versa, and what happens to each component as the system switches between states) --> | <!-- Show a network/ circuit diagram of your team's Lac switch. Include a paragraph to explain how it works (i.e., how to switch the system from on to off and vice versa, and what happens to each component as the system switches between states) --> | ||

<b>How the Switch Works</b><br> | |||

Our Sweet Cyan switch works based on the relationship between the LacI protein, IPTG, and CFP. For the transcription of CFP to take place, the LacI regulated promoter (see P<sub>CFP</sub> in circuit diagram below) must be active. Because the LacI protein inhibits the CFP promoter, CFP will not be produced or is "turned off" in the presence of the LacI protein. | |||

[[Image:Circuit_Diagram_of_Sweet_Cyan_Switch.PNG|thumb|600px|center|Circuit Diagram for Sweet Cyan Switch<br>P<sub>Lac</sub> represents the LacI promoter and P<sub>CFP</sub> represents the CFP promoter]]<br> | |||

The switch is designed so that under normal conditions LacI is produced, the LacI regulated promoter (P<sub>CFP</sub>) is consequently inhibited, and CFP production is inhibited. However, when IPTG is added to the system, it binds to the LacI protein that is being created and subsequently prevents the LacI from inhibiting P<sub>CFP</sub>, once P<sub>CFP</sub> is no longer inhibited, the system produces CFP. When the CFP promoter is active, the system will produce a fluorescent cyan color. | |||

<br> | |||

A Plasmid map of the system is included for reference below. | |||

[[Image:Sweet_Cyan_Plasmid_Map.png|thumb|400px|center|Plasmid Map of "Sweet Cyan"]] | |||

<br><br> | |||

<!-- These are lines breaks for spacing purposes. You can add or delete these as needed --> | <!-- These are lines breaks for spacing purposes. You can add or delete these as needed --> | ||

| Line 279: | Line 286: | ||

<!-- These are lines breaks for spacing purposes. You can add or delete these as needed --> | <!-- These are lines breaks for spacing purposes. You can add or delete these as needed --> | ||

==Luciferase: An Alternative to CFP== | |||

Since CFP will only fluoresce when exposed to ultraviolet light, a possible alternative to CFP that is bioluminescent is Luciferase. Luciferase would likely be a more feasable solution to a biodegradable light source than CFP because it does not require exposure to an additional light source before it will emit light. There are BioBrick parts, such as [http://partsregistry.org/wiki/index.php?title=Part:BBa_I712019 BBa_I712019] or [http://partsregistry.org/Part:BBa_J52008 BBa_J52008] from [http://partsregistry.org Parts Registry] which are possible candidates for creating a bio-luminescent device. | |||

==Testing: Modeling and GFP imaging== | ==Testing: Modeling and GFP imaging== | ||

| Line 403: | Line 412: | ||

[[Image:Bgal0.045.jpg|thumb|right|210px|Figure 2: Bgal Concentration vs. Time with I = 0.045]] | [[Image:Bgal0.045.jpg|thumb|right|210px|Figure 2: Bgal Concentration vs. Time with I = 0.045]] | ||

[[Image:Bgal0.064.jpg|thumb|right|210px|Figure 3: Bgal Concentration vs. Time with I = 0.064]] | [[Image:Bgal0.064.jpg|thumb|right|210px|Figure 3: Bgal Concentration vs. Time with I = 0.064]] | ||

[[Image:AllIPTG.jpg|thumb|right|210px|Figure 4: Bgal Concentration vs. Time with all three]] | |||

<br><br><br><br><br><br> | |||

===An interactive model=== | ===An interactive model=== | ||

| Line 410: | Line 421: | ||

<br> | <br> | ||

The initial concentration of IPTG has a direct influence on the rate of βgal production and thus has a point where this rate is in equilibrium to the rate of βgal degradation which increases with the production of more βgal. Because the rate at which β-galactosidase is being produced must interact with the degradation rate of β-galactosidase, the production starts to cap off at around time = 100 with an approaching βgal concentration of about 4.52 x 10<sup>-4</sup> where slope is 0, reaching saturation as seen in the original model. As the initial concentration of IPTG goes down (say 0.045), β-galactoside production rate isn't in equilibrium with the degradation rate till quite some time after an initial spike due to the always available mRNA seen as the IPTG input decreases, and so β-galactoside production is never 0. Even at this point however, the output of IPTG is still not quite sustained although a pattern is evident. As soon as the concentration gets to around 0.064, visible equilibrium is seen between production and degradation at a time of around 10 and a concentration of about 2.56 x 10<sup>-5</sup> and thus a threshold is found with this sustainable βgal output where the equilibrium concentration is equal to the concentration caused by the initial mRNA. | The initial concentration of IPTG has a direct influence on the rate of βgal production and thus has a point where this rate is in equilibrium to the rate of βgal degradation which increases with the production of more βgal. Because the rate at which β-galactosidase is being produced must interact with the degradation rate of β-galactosidase, the production starts to cap off at around time = 100 with an approaching βgal concentration of about 4.52 x 10<sup>-4</sup> where slope is 0, reaching saturation as seen in the original model. As the initial concentration of IPTG goes down (say 0.045), β-galactoside production rate isn't in equilibrium with the degradation rate till quite some time after an initial spike due to the always available mRNA seen as the IPTG input decreases, and so β-galactoside production is never 0. Even at this point however, the output of IPTG is still not quite sustained although a pattern is evident. As soon as the concentration gets to around 0.064, visible equilibrium is seen between production and degradation at a time of around 10 and a concentration of about 2.56 x 10<sup>-5</sup> and thus a threshold is found with this sustainable βgal output where the equilibrium concentration is equal to the concentration caused by the initial mRNA. All four initial concentrations can be compared in figure 4. | ||

<br> | <br> | ||

| Line 440: | Line 451: | ||

===Collecting imperical values to improve the model=== | ===Collecting imperical values to improve the model=== | ||

We used a microscopy imaging technique to determine the production rate of GFP yeast. Based on our collected data, we were able to determine a "real" value for the maximum GFP production rate for the given conditions. | We used a microscopy imaging technique to determine the production rate of GFP yeast. Based on our collected data, we were able to determine a "real" value for the maximum GFP production rate for the given conditions. | ||

<br> | <br> | ||

| Line 462: | Line 473: | ||

To find the maximum rate of GFP production, the derivative of the 4th order polynomial (above) was plotted in MATLAB and the maximum y value was found. The plot of the 3rd order derivative polynomial can be seen below. | To find the maximum rate of GFP production, the derivative of the 4th order polynomial (above) was plotted in MATLAB and the maximum y value was found. The plot of the 3rd order derivative polynomial can be seen below. | ||

[[Image:Best_Fit_Derivative_Plot.png|700px|center|Plot of the Derivative of the "Best Fit" Polynomial]] <br> | [[Image:Best_Fit_Derivative_Plot.png|700px|center|Plot of the Derivative of the "Best Fit" Polynomial]] <br> | ||

The maximum rate of GFP production corresponds to the maximum y value of the derivative plot which was found to be 3.299. Ideally, the GFP production rate measured by this method could be entered as a value for | The maximum rate of GFP production corresponds to the maximum y value of the derivative plot which was found to be 3.299. Ideally, the GFP production rate measured by this method could be entered as a value for a<sup>M</sup><sub>G</sub> (GFP transcription rate) in the Ceroni et al. model. To better improve the accuracy of the curves (and therefor the GFP production rate), a significantly larger number of cells should be tracked, their data averaged, and all of the plots recreated using the new data. | ||

==Human Practices== | |||

===Stakeholder Assessment=== | |||

==Stakeholder Assessment== | |||

<br> | <br> | ||

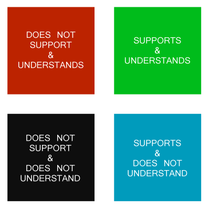

[[Image:Stakeholder-matrix.png|thumb|210px|right|'''Stakeholder Matrix''']] | [[Image:Stakeholder-matrix.png|thumb|210px|right|'''Stakeholder Matrix''']] | ||

'''SUPPORTS & UNDERSTANDS'''<br> | '''SUPPORTS & UNDERSTANDS'''<br> | ||

When consumers/investors actually understand how a product works and the logic or science that is behind it, they fall into this supports & and understands category. Perhaps this group understands that negative implications may follow the use of E. coli, but these people also know that the risk is minimal enough for commercial use. As E. coli is naturally in one's intestines, the risks of this bacterium may seem negligible. There are also those that may find the use of this product outweighs the necessary risks that come with it. | |||

Usually scientists, engineers, doctors, or maybe those just knowledgeable of common bacteria in this case are going to fall into this group. Those that do might see the benefits of using such a green device (or in this case blue) for such common practices such as camping, scouting, or spelunking. This group would certainly be the most perceptive of the different groups. | |||

<br><br> | |||

'''DOES NOT SUPPORT & UNDERSTANDS'''<br> | '''DOES NOT SUPPORT & UNDERSTANDS'''<br> | ||

<!--Emily-->A group that understands the technology behind the device but would not support its construction and use could be competition, stakeholders in current technology that meet the customer needs that this new device would try and cater to. Also, scientists, engineers, and healthcare personnel who know the implications of using ''E. coli'' in a biodegradable device may oppose its commercialization, as mistakes made in production or consumer handling of the product could prove harmful to human and environmental health. | <!--Emily-->A group that understands the technology behind the device but would not support its construction and use could be competition, stakeholders in current technology that meet the customer needs that this new device would try and cater to. Also, scientists, engineers, and healthcare personnel who know the implications of using ''E. coli'' in a biodegradable device may oppose its commercialization, as mistakes made in production or consumer handling of the product could prove harmful to human and environmental health. | ||

Public and laymen knowledge of ''E. coli'' may consist of only what they hear in the news, which often relates to food contamination scares; for this reason, stakeholders of the device itself may not support its production if they believe that widespread stigma may prevent successful marketing and sales campaigns.<br><br> | Public and laymen knowledge of ''E. coli'' may consist of only what they hear in the news, which often relates to food contamination scares; for this reason, stakeholders of the device itself may not support its production if they believe that widespread stigma may prevent successful marketing and sales campaigns.<br><br> | ||

'''SUPPORTS & DOES NOT UNDERSTAND'''<br> | '''SUPPORTS & DOES NOT UNDERSTAND'''<br> | ||

This group does not understand the technology behind a device, however they still support the construction and use of the technology. Stakeholders that fall into this group are likely to benefit from the success of the proposed technology therefore they support it even though they are not well versed in how the technology works. Because of their lack of knowledge, this group may not fully understand why the device is safe to use despite the potential risks of using a biodegradable device that is powered by E. coli bacteria or they are too focused on the potential success of the device to care about the risks. Additionally, this group sees the benefits of the device such as an emergency, saftey, or warning light without needing to understand the technology that is driving the device. | |||

<br> | |||

'''DOES NOT SUPPORT & DOES NOT UNDERSTAND'''<br> | '''DOES NOT SUPPORT & DOES NOT UNDERSTAND'''<br> | ||

In general, when the common person hears about E. coli, they assume that it is the strain that causes great harm to the human species. Because of this, those who do not fully understand that many strains of E. coli that are harmless to humans exist. By using a biodegradable device that is powered with E. coli, it runs a risk that the average consumer would shy away from this type of light source because of the generalized fear of the bacteria. Therefore, those who do not fully understand that there are completely harmless types of E. coli and that they can be quite useful in our everyday life would not support such a product. This product would lack their support simply because of lack of knowledge and a general public opinion towards E. coli. | This is a group of potential consumers that choose not to support the product and does not understand the technology behind it. In general, when the common person hears about E. coli, they assume that it is the strain that causes great harm to the human species. Because of this, those who do not fully understand that many strains of E. coli that are harmless to humans exist. By using a biodegradable device that is powered with E. coli, it runs a risk that the average consumer would shy away from this type of light source because of the generalized fear of the bacteria. Therefore, those who do not fully understand that there are completely harmless types of E. coli and that they can be quite useful in our everyday life would not support such a product. This product would lack their support simply because of lack of knowledge and a general public opinion towards E. coli. | ||

<!--Wait until Unit 3 to fill this in. Demonstrate that you have considered the societal aspects of your project - what could go wrong? Is it implementable? Etc.--> | <!--Wait until Unit 3 to fill this in. Demonstrate that you have considered the societal aspects of your project - what could go wrong? Is it implementable? Etc.--> | ||

==Our Team== | ==Our Team== | ||

| Line 516: | Line 525: | ||

[[Image:IMG 1565.JPG |thumb|noframe|130px|left|'''Sean Hector''']] | [[Image:IMG 1565.JPG |thumb|noframe|130px|left|'''Sean Hector''']] | ||

<br><br> | |||

* My name is Edgil Hector (Sean), and I am a student majoring in biomedical engineering. I am taking BME 494 because the subject is relevant to my interests, and the class counts as a required technical elective. An interesting fact about me is that I am the most indecisive human being on the planet. | * My name is Edgil Hector (Sean), and I am a student majoring in biomedical engineering. I am taking BME 494 because the subject is relevant to my interests, and the class counts as a required technical elective. An interesting fact about me is that I am the most indecisive human being on the planet. | ||

| Line 529: | Line 538: | ||

<br><br> | |||

* My name is Julia Smith, and I am a senior majoring in Biomedical Engineering. I am taking BME 494 because I am extremely interested in synthetic biology. An interesting fact about me is that in addition to my nerdy side and love of academic learning, I train reining horses. | * My name is Julia Smith, and I am a senior majoring in Biomedical Engineering. I am taking BME 494 because I am extremely interested in synthetic biology. An interesting fact about me is that in addition to my nerdy side and love of academic learning, I train reining horses. | ||

Latest revision as of 22:58, 30 April 2013

Home People Course Projects Course Materials Schedule Photos Wiki Editing Help

|

Overview & PurposeEscherichia coli, commonly referred to as E. coli, has many different strains. The most commonly known serotypes of these bacteria can cause serious food poisoning or even fatality in humans. However, most strains are completely harmless. These strains are usually found in the gut of the host and help by producing K2 and helping with digestion. The presence of these bacteria is very beneficial for it helps to prevent pathogenic bacteria from being present in the intestine.[1] The Lac switch that we have created in the genetic coding of E. coli bacteria produces a glowing blue color that initially runs off of glucose and eventually runs off of lactose. With this technology, we can create a glow stick that can be used in emergency kits that will provide light in dire situations. By using a non-harmful strain of E. coli, we can create an environmental conscious and biodegradable glow stick that will not cause harm to the surroundings. This model would act as a proof-of-concept in the development of the device; the BioBricks available in the Parts Registry facilitated easy construction and testing of the model but do not contain the luminescent components the group would use in the distributed device. The cyan fluorescent protein (CFP), which is used in the proof-of-concept model, would necessitate the use of ultra-violet light to observe the fluorescent output. This would not be implementable in a model geared toward commercialization. Instead, the final model would use luciferase (such as BBa_I712019 or BBa_J52008), which would not require the use of external stimulants to operate. This technology will prove to be very helpful for hunters or those who are outdoors for they will not have to worry about disposing of their light source. Used like a regular glow stick, the different components of the device will remain separated and will be mixed together to produce light once a certain amount of force is applied. Background

"Only LacZ and LacY appear to be necessary for lactose catabolism" [3].

Design: Our genetic circuitOur gene switchTo create our gene switch, we chose to replace β-galactosidase with a gene coding for a variant of GFP (green fluorescent protein). The switch is active or “on” in the presence of IPTG (Isopropylthiogalactoside) and causes the production of a cyan fluorescent color. Additionally, we did not want our switch to be influenced by the presence of glucose so we chose a promoter that is not sensitive to the CAP-cAMP complex and as a result IPTG is the sole input that causes an effect to the switch. Device Structure and PartsThe BioBricks for our design came from the Registry of Standard Biological Parts. Our system utilized two main BioBricks along with an appropriate vector backbone (see figure below).  IPTG-Inducible Lac Promoter

How the Switch Works  PLac represents the LacI promoter and PCFP represents the CFP promoter The switch is designed so that under normal conditions LacI is produced, the LacI regulated promoter (PCFP) is consequently inhibited, and CFP production is inhibited. However, when IPTG is added to the system, it binds to the LacI protein that is being created and subsequently prevents the LacI from inhibiting PCFP, once PCFP is no longer inhibited, the system produces CFP. When the CFP promoter is active, the system will produce a fluorescent cyan color.

Building: Assembly scheme The assembly strategy employed in the design of this device is a Type IIS assembly strategy. The steps and procedures involved in this single-pot assembly are described below. MutagenesisOne of the parts chosen by our group contains a BsmBI cut site, which would disrupt the digestion and ligation process further along the assembly strategy. In order to counteract this, the part is subjected to mutagenesis to alter a selected base pair within the DNA to eliminate the BsmBI cut site while keeping the integrity of the coding sequence intact. This site-directed base substitution is performed using two primers with centrally located substitution sites to alter the selected base pair on a methylated plasmid. After the part has completed the mutagenesis, the DNA sequence (which is linear at this point in time) undergoes in vitro recombination reaction. The host cell then "circularizes" the mutated part DNA and digests the original methylated plasmid. If the methylation of the original plasmid is skipped, an additional purification step would be necessary to extract the mutated plasmid.[5]

PCRPCR, or polymerase chain reaction, is then used to amplify the DNA sequences and create modular fragments for ease of assembly. A DNA fragment is combined with its forward and reverse primers, nucleotides, and DNA polymerase. This mixture is then inserted into a thermal cycler, which cycles the internal temperature with predetermined values. These changes in temperature cause the DNA to separate, the primers to pair with their respective DNA strands, the DNA polymerase to activate, and a new DNA strand to be formed. The thermal cycling procedure, listed below, is continued until the specified fragment is amplified sufficiently for use. Thermal Cycling

Digestion and ligation reactionThe Type IIS assembly strategy employs a single-pot assembly, wherein digestion and ligation occur in tandem. To prevent the futile digestion/ligation loop that could result from this assembly strategy, the BsmBI restriction enzyme is used. BsmBI is useful in this scenario because its binding site is remote from its cutting site. In the digestion and ligation reaction, BsmBI binds to its binding site, CGTCTC, and cuts at a location further along the DNA strand. This creates a 4 base pair "sticky overhang." Complementary "sticky overhangs" then pair up and are connected by the ligase. The thermal cycling procedure used in the digestion and ligation reaction is shown below. Thermal Cycling

Parts and primersThe following table lists the BioBricks used in the construction of the Sweet Cyan device. The individual parts can be found with a simple search of the part IDs at the Parts Registry.

Luciferase: An Alternative to CFPSince CFP will only fluoresce when exposed to ultraviolet light, a possible alternative to CFP that is bioluminescent is Luciferase. Luciferase would likely be a more feasable solution to a biodegradable light source than CFP because it does not require exposure to an additional light source before it will emit light. There are BioBrick parts, such as BBa_I712019 or BBa_J52008 from Parts Registry which are possible candidates for creating a bio-luminescent device. Testing: Modeling and GFP imagingA lac switch modelWe used a previously published synthetic switch, developed by Ceroni et al.[6], to understand how our system could potentially be modeled and simulated. The graphic to the right depicts the relationships between the parameters of the lac operon switch described by Ceroni using a network diagram illustration. The parameters shown in the illustration relate to cell processes and could be used in forming a cohesive mathematical model of the cell's operation. In order to approximate the behavior of this set-up, a mathematical model can be developed based upon the relationships between the processes found in the cell. These relationships can be expressed in mathematical terms using numbers that relate to the system, including creation or decay rates, concentrations, or various constants. The actual values for these parameters can be sourced from experimentation, literature, or a predefined steady-state. If a model is well-defined and the necessary parameters known, a person may use the model to ascertain the state of a cell at a given point in time. For example, if an experimenter wanted to know the decay of the GFP protein molecules at a given point in time in a single cell, the following equation could be written using the notation found in the table below. Decay = G × λG/L The formula takes the concentration of the GFP protein in molecules per cell ("G") and multiplies it by the protein degradation rate in minutes-1 ("λG/L"). This results in a decay value for GPF in molecules per minute per cell. The Ceroni et al. model and the network diagram illustration use the table of variables and parameters seen below in their representation of the lac switch. The variables related to a particular cell process are located near to that process in the network diagram illustration.

An interactive modelWe used a model of the natural Lac operon to understand how changing the parameter values changes the behavior of the system. By changing the initial concentration of input (IPTG in this case), we were able to estimate the threshold that produces an "on" state in the system. Initially, the code had the concentration at 0.32 which is seen in the β-galactoside (Bgal concentration) vs. time plot (Figure 1). This value was changed again to 0.045 in determining the threshold that produces this "on" state (Figure 2). After proceeding to go up and down with these a values, a threshold was indeed found where the output concentration of IPTG was sustained and is about 0.064 (Figure 3).

Collecting imperical values to improve the modelWe used a microscopy imaging technique to determine the production rate of GFP yeast. Based on our collected data, we were able to determine a "real" value for the maximum GFP production rate for the given conditions.

Images shown were taken at 7, 10, 16, and 20 hours respectively.

To find the maximum rate of GFP production, the derivative of the 4th order polynomial (above) was plotted in MATLAB and the maximum y value was found. The plot of the 3rd order derivative polynomial can be seen below.  The maximum rate of GFP production corresponds to the maximum y value of the derivative plot which was found to be 3.299. Ideally, the GFP production rate measured by this method could be entered as a value for aMG (GFP transcription rate) in the Ceroni et al. model. To better improve the accuracy of the curves (and therefor the GFP production rate), a significantly larger number of cells should be tracked, their data averaged, and all of the plots recreated using the new data. Human PracticesStakeholder Assessment

SUPPORTS & UNDERSTANDS Usually scientists, engineers, doctors, or maybe those just knowledgeable of common bacteria in this case are going to fall into this group. Those that do might see the benefits of using such a green device (or in this case blue) for such common practices such as camping, scouting, or spelunking. This group would certainly be the most perceptive of the different groups.

Public and laymen knowledge of E. coli may consist of only what they hear in the news, which often relates to food contamination scares; for this reason, stakeholders of the device itself may not support its production if they believe that widespread stigma may prevent successful marketing and sales campaigns. SUPPORTS & DOES NOT UNDERSTAND

DOES NOT SUPPORT & DOES NOT UNDERSTAND

Our Team

Works Cited |